firstbase

Guru

- Joined

- Nov 6, 2016

- Messages

- 1,644

- Location

- United States

- Vessel Name

- Black Eyed Susan

- Vessel Make

- Grand Banks 42' Classic

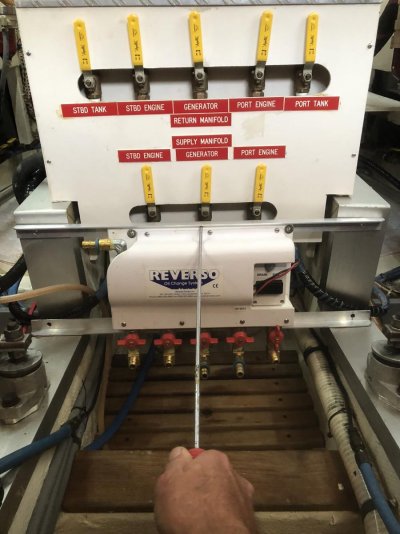

Still messing around with installing my (overkill) Reverso oil change system. Have new hoses from the oil sumps installed and ready to connect up to the pump after I finish installing it. Not concerned with the gears or the generator yet. Saving those for later. The only place I could find to reasonably install it is at the base of the fuel manifold, see pic. Using two aluminium cross bars bolted into the end of the generator supports/stringers.

After connecting the fittings on the pump and aiming them forward I find that it would be much better to flip them to aim towards the stern, under the generator platform. This would keep the hoses out of harms way and allow more room for general generator maintenance. It also would allow an easier feed in from the engines. To do so I need to bring the hoses to the rear of the trannys and then through the stringers supporting the generator. See pics, not installed yet so had to hold it in place with along screw driver.

There is a 2.5"-3" hole on either side for the fuel lines to come in to the manifold. They are lined with a large plastic "grommet" for lack of a better term. I need to add a hole on each side and don't know if the stringer is solid, hollow, wood, whatever. The exterior is covered with fiberglass cloth. What should I expect if I try to use a hole saw to make an opening? If I do make the openings what should I line them with?

Also, any comments or suggestions on the install greatly appreciated. It's really not too late for me to stop the madness and just use a hand pump!

After connecting the fittings on the pump and aiming them forward I find that it would be much better to flip them to aim towards the stern, under the generator platform. This would keep the hoses out of harms way and allow more room for general generator maintenance. It also would allow an easier feed in from the engines. To do so I need to bring the hoses to the rear of the trannys and then through the stringers supporting the generator. See pics, not installed yet so had to hold it in place with along screw driver.

There is a 2.5"-3" hole on either side for the fuel lines to come in to the manifold. They are lined with a large plastic "grommet" for lack of a better term. I need to add a hole on each side and don't know if the stringer is solid, hollow, wood, whatever. The exterior is covered with fiberglass cloth. What should I expect if I try to use a hole saw to make an opening? If I do make the openings what should I line them with?

Also, any comments or suggestions on the install greatly appreciated. It's really not too late for me to stop the madness and just use a hand pump!