TrawlerJoe

Veteran Member

Hi all,

Been lurking here for quite some time, absorbing advice, etc. After a dozen years, I sold my Cape Dory 28 trawler and bought a Legacy 34 flybridge. Not quite a trawler, but... maybe I can still get help here?

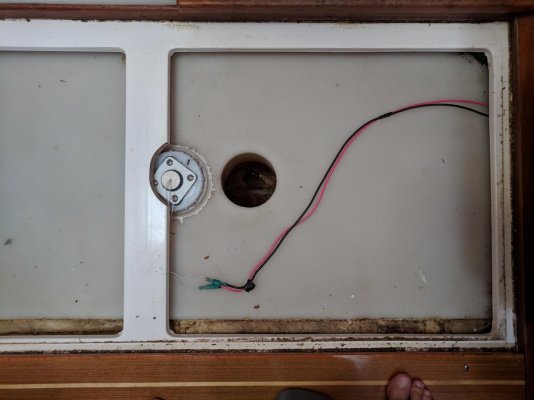

I have an issue with the holding tank that I don't understand. Viewed from the top, there are two cylindrical recesses. The one on the left in the picture is the tank watch sensor. The one on the right is just open, and something is obviously wrong here. Liquid waste seeps into the opening from the bottom, and the smell of course escapes into the boat. Down inside that opening, it appears there is some kind of tube/pipe running horizontally, plus it appears there is some kind of foam (possibly the expanding spray-in foam). All of this saturates with waste. For the moment, I taped plastic over the opening to help contain smell.

What is the purpose of this opening? Should I just seal it up?

Thanks for any advice.

Joe

Been lurking here for quite some time, absorbing advice, etc. After a dozen years, I sold my Cape Dory 28 trawler and bought a Legacy 34 flybridge. Not quite a trawler, but... maybe I can still get help here?

I have an issue with the holding tank that I don't understand. Viewed from the top, there are two cylindrical recesses. The one on the left in the picture is the tank watch sensor. The one on the right is just open, and something is obviously wrong here. Liquid waste seeps into the opening from the bottom, and the smell of course escapes into the boat. Down inside that opening, it appears there is some kind of tube/pipe running horizontally, plus it appears there is some kind of foam (possibly the expanding spray-in foam). All of this saturates with waste. For the moment, I taped plastic over the opening to help contain smell.

What is the purpose of this opening? Should I just seal it up?

Thanks for any advice.

Joe