sbman

Guru

- Joined

- Jul 25, 2017

- Messages

- 828

- Location

- USA

- Vessel Name

- Second Chance

- Vessel Make

- 42' Uniflite Double Cabin

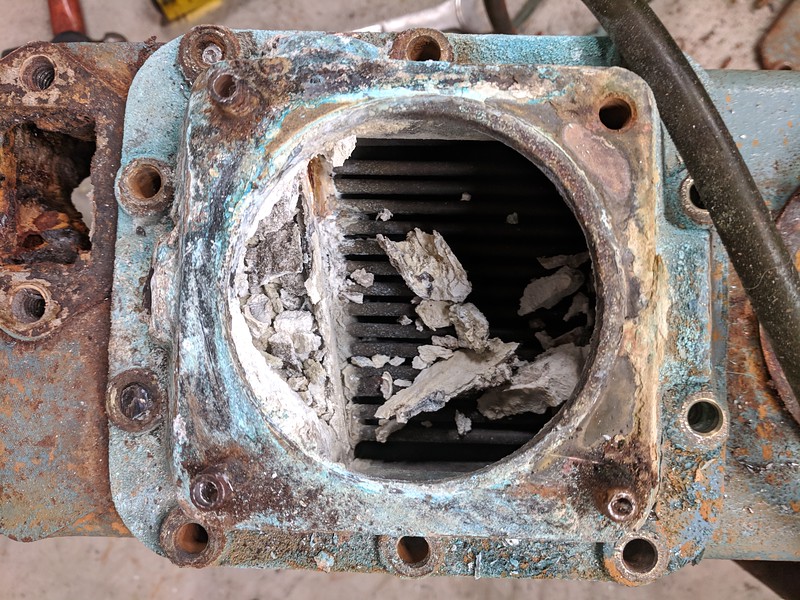

If there is interest from anyone to follow along, I thought I'd post a thread on the overhaul process of a Johnson & Towers Detroit 671 from 1977.

This really isn't a recommended kind of thing to do. If the boat was worth more, a repower would be appropriate. But my boat is a 42' 1977 Uniflite Double Cabin commonly referred to as a 'blister boat' due to a fire retardant additive used at that time. It has small bumps in various areas that would cost a lot to have repaired and then they come back over time anyways. It will never be worth much financially, but I am happy to use the boat as long as it suits my purposes. However, one engine was neglected by a former owner (along with other items) and it needs to be rebuilt, so I'm doing that.

The boat is on the hard for this process along with a full bottom job, thru hulls service and a few other items.

This really isn't a recommended kind of thing to do. If the boat was worth more, a repower would be appropriate. But my boat is a 42' 1977 Uniflite Double Cabin commonly referred to as a 'blister boat' due to a fire retardant additive used at that time. It has small bumps in various areas that would cost a lot to have repaired and then they come back over time anyways. It will never be worth much financially, but I am happy to use the boat as long as it suits my purposes. However, one engine was neglected by a former owner (along with other items) and it needs to be rebuilt, so I'm doing that.

The boat is on the hard for this process along with a full bottom job, thru hulls service and a few other items.