A truly flexible shaft coupler, like an Aqua Drive, requires some room to install it. From your earlier photo it appears you don't have much exposed shaft between the transmission and the stuffing box/shaft log. An Aqua Drive is intended to allow a softer engine mounting for less or no vibration in the boat. You cant simply put soft engine mounts on a hard-coupled engine because the engine will move around too much on the mounts and stress and wear the driveline and cutless bearings. But by putting what in essence is a U-joint in the driveline after the engine, you can now use soft mounts as the engine's movement will be compensated for by the U-joint coupler. Here is the URL for Aqua Drive if you want to find out more about them

http://www.aquadrive.net/ There may be other makes or types of flexible couplings--- Aqua Drive is the only one I know about.

I'm not familiar enough with hull construction to know how easy or hard it is to change the angle of a prop shaft as it comes through the hull. It sounds to me like it's a major job but I simply don't know. But if this is not done, or can't be done, and if the alignment of your engine and drive shaft are correct now, then changing the height or angle of you engine will mis-align it with the propshaft and you'll have a new problem to deal with.

Propshafts are flexible. The amount of flexibility will be dependent on the length of the shaft and length of its unsupported segments. This is generally the greatest in a twin-engine boat like ours. What this means is that a certain amount of mis-alignment between the engine/transmission and the shaft can occur and be compensated for by the shaft's flexing. The symptom is often a vibration and over time it's hard on everything--- cutless bearings, motor mounts, and the shaft itself.

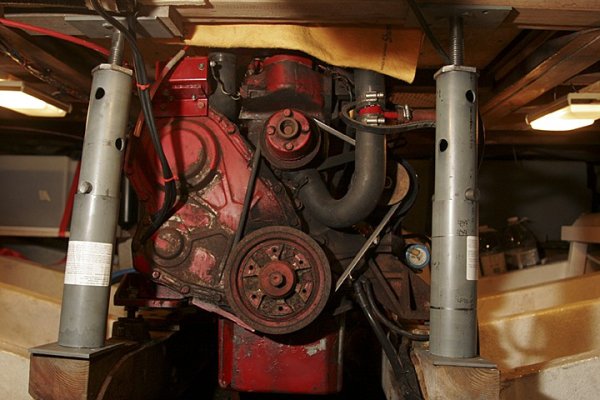

In a single like yours there seems to be very little shaft length between the shaft log and the shaft coupler on the transmission's output shaft. And I'm guessing there's not much exposed shaft between the rear bearing and the prop itself. So I would think there is little to no opportunity for the shaft in your boat to flex. Do you get a lot of vibration when you run the boat? Tough question to judge because vibration can be generated by a lot of things.

A good first step is to do what others have suggested and first check the alignment of the engine to the shaft. This is relatively easily done by separating the shaft coupler and sliding the shaft back a fraction of an inche and measuring with a feeler gauge all the way aorund the gap between the two coupler halves. If the gap is the same all the way around then the engine and shaft are in the correct alignment. There is a certain amount of tolerance in this measurement-- our diesel shop has told us what it is but I don't remember so if you decide to do this yourself check with a shop to get the correct tolerance number.

If you find the alignment is correct, then it would seem you have three choices.

One, leave the engine where it is, lower it, and realign the shaft itself to the engine by changing the angle the shaft comes through the hull. Major big job I would think but I don't know..

Two, the coupler can be removed, the shaft shortened a little bit (you don't have much to work with here judging from your photo) and the engine slid back and lowered a wee bit in the same alignment to mate up with the shorter shaft.* However, I'm not sure this would actually get you the clearance you need so work out the geometry very carefully before you decide to try this.

Three, relieve the underside of the hatch in the manner some earlier posters have suggested.