ak-guy

Senior Member

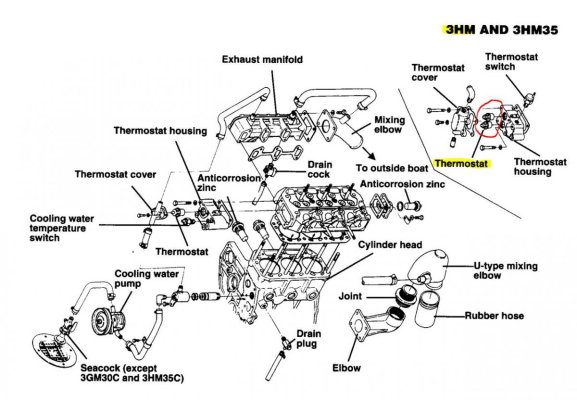

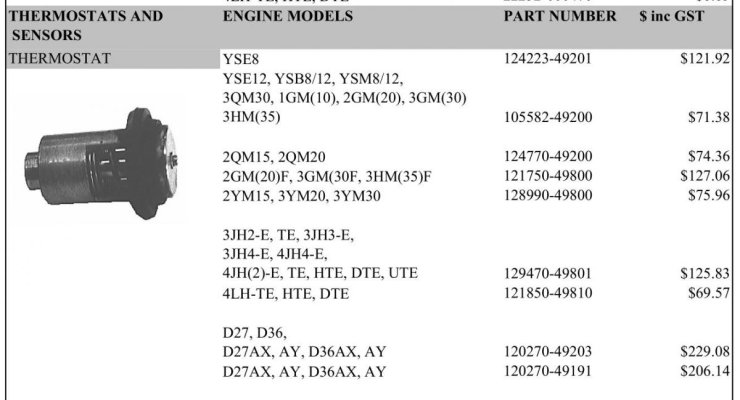

I have an older Yanmar 3HM. It is keel cooled and seems to be in good shape. The 3HM was designed for raw water cooling but was adapted to keel cooling by the builder. The engine temp runs at around 135-140F. I have looked into changing the thermostats to a higher temp but that option is not available. There is a way to do it with an external thermostat and I bought the thermostat and misc plumbing but decided not to bother with it.

The boat was on the hard all winter and one of the maintenance jobs I did was flushing and cleaning the cooling system with a radiator flush chemical. Before the boat ran at 140F or so. Now after cleaning the cooling system it is about 122F. The spec for the thermostats is opening at 108F and fully open at 126F so I guess it is working as it is supposed to. Disappointing though as I thought 140 was kind of low.

The reason I thought cleaning the cooling system might be good was that when I ran the engine wide open the temp would climb fairly high. I haven't tried max rpm since cleaning but I will.

The boat was on the hard all winter and one of the maintenance jobs I did was flushing and cleaning the cooling system with a radiator flush chemical. Before the boat ran at 140F or so. Now after cleaning the cooling system it is about 122F. The spec for the thermostats is opening at 108F and fully open at 126F so I guess it is working as it is supposed to. Disappointing though as I thought 140 was kind of low.

The reason I thought cleaning the cooling system might be good was that when I ran the engine wide open the temp would climb fairly high. I haven't tried max rpm since cleaning but I will.