skipperdude

Guru

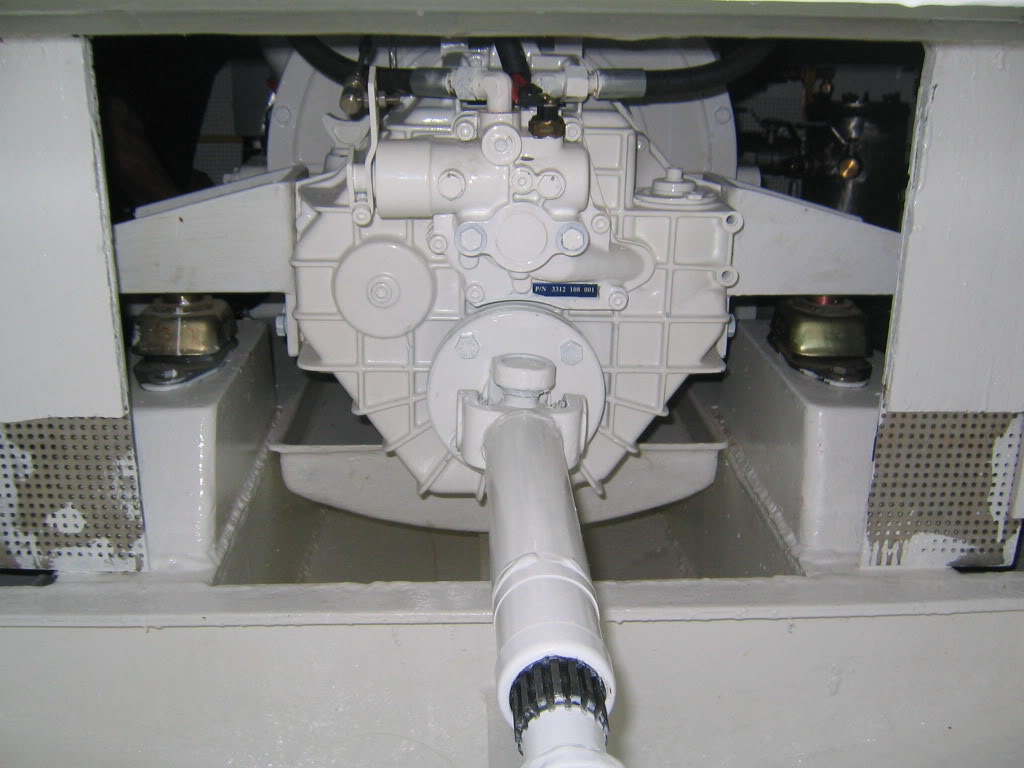

Does anyone have this sort of set up as far as motor mounts go?

There doesn't seem to be any vibration damper. the mounts hang over the stringers and seem to be hard mounted with just bolts.

I was thinking of changing the mounts to provide for quiet and less vibration.

I'm thinking if I changed anything I would have to reconfigure the entire mounting system.

The 4 th pic shows the actual mount as far as where the bottom of the engine is mounted to the stringers.

SD

*

-- Edited by skipperdude on Monday 23rd of January 2012 11:35:06 AM

There doesn't seem to be any vibration damper. the mounts hang over the stringers and seem to be hard mounted with just bolts.

I was thinking of changing the mounts to provide for quiet and less vibration.

I'm thinking if I changed anything I would have to reconfigure the entire mounting system.

The 4 th pic shows the actual mount as far as where the bottom of the engine is mounted to the stringers.

SD

*

-- Edited by skipperdude on Monday 23rd of January 2012 11:35:06 AM