BobMc

Senior Member

- Joined

- Feb 5, 2012

- Messages

- 112

- Vessel Name

- Sanderling

- Vessel Make

- DeFever 41

That issue with the Simms pump only applies to the FL-120, not to the FL-135. The OP said he had a FL-135.

A much bigger problem than the final filtration is the 50 hour Simms pump oil change. A friend of mine who rebuilds Lehmans for a living says many owners neglect that maintenance and it has caused many Simms failures. Do yourself a favour, Simms owners, change the oil every 50 hours even if it is entirely a PITA.

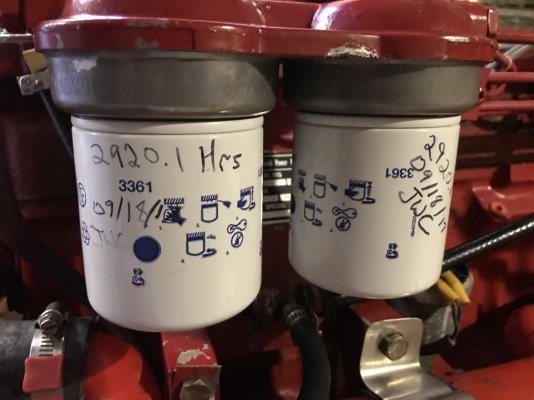

is a simple gauge of filter replacement whereas the CAVs are hit-and-miss, change it because-it-feels-good or never change it because out-of-sight-out-of-mind.

is a simple gauge of filter replacement whereas the CAVs are hit-and-miss, change it because-it-feels-good or never change it because out-of-sight-out-of-mind.