Respite802

Newbie

My boat is powered with a single Cummins 6BT. It has something like 3200 hours on it. When I go to start it I often get just a solenoid click. Pressing the start several times will finally get the starter motor to crank. It almost always takes more than on press, but never more than 4 or 5. It’s important to note that the starter batter voltage drops some when the button is pressed. It doesn’t drop much which to me indicates that current is flowing.

It’s not all the confidence inspiring but its been that way in the 3 years I’ve be owner and I’ve learned to live with it.

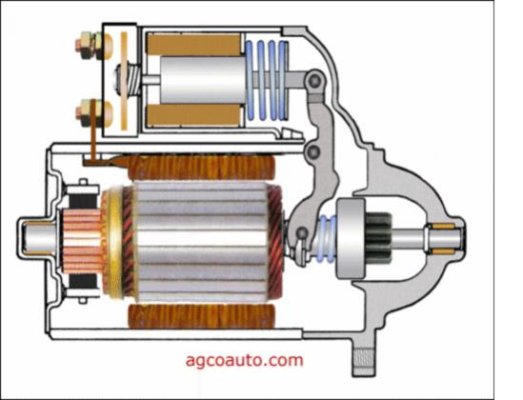

Now that the boating season up north is coming to an end I’d like to see about addressing the issue before I get stranded somewhere with a 30knot wind blowing me onto some pointy rocks. My thoughts based on experience is that the starter motor brushes could be in need of replacement. My other though is engine/ starter motor grounding but I’ve checked that and it’s extremely unlikely.

Anyone have some insight before I start throwing cash at the problem ?

Thanks

Dave

Nordic Tug 32-135

It’s not all the confidence inspiring but its been that way in the 3 years I’ve be owner and I’ve learned to live with it.

Now that the boating season up north is coming to an end I’d like to see about addressing the issue before I get stranded somewhere with a 30knot wind blowing me onto some pointy rocks. My thoughts based on experience is that the starter motor brushes could be in need of replacement. My other though is engine/ starter motor grounding but I’ve checked that and it’s extremely unlikely.

Anyone have some insight before I start throwing cash at the problem ?

Thanks

Dave

Nordic Tug 32-135