Today I cut the hole using a jig saw. Sanded it with a curved block till smooth and got the exact same size as the port. That mahogany board they built the hull side of back in 1970 is one solid piece, a very wide log!

I then epoxied the mahogany edge and where the port inner ring sits.

Then I coated with some Zinsser bulls eye primer. About the best primer I have found so far.

I test fit the porthole mirror and it looks good. The backside of the mirror is protected with a plate of aluminum bolted on. And it is sealed with some rubber cement to keep out water.

It can be held open with a bit of chrome chain I had, the link slips into the lock down arm of the port window. Other end has an eye hook and just happens to fit in the hole vacated by the DC light I had to relocate farther over so the port window could open up all the way.

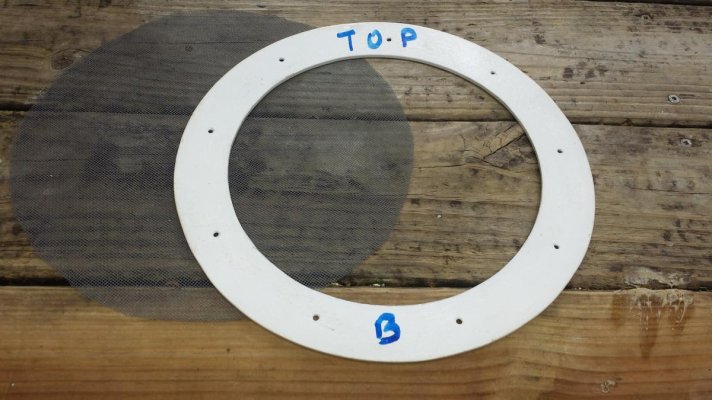

The outer ring I fit but need to get some rubber cement to glue the screen onto the ring before I screw it onto the wood.

I may just use rubber cement, and of course test it with a water hose.

The inner ring has a wide inner ridge as a tight fit to the wood. Farther back is concave area which could fit some foam rubber gasket, but I don't think it is needed.

Those bulbs I just put in are LED, three colors of white. You select which color by rabidly turning it on and off. They are very bright, supposed to be equivalent to 40 watts. I burned my arm on the incandescent globes when working on this project, so they are history.

https://www.amazon.com/gp/product/B07FP6JFD8/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1