LeoKa

Guru

- Joined

- Apr 15, 2017

- Messages

- 1,150

- Location

- USA

- Vessel Name

- Ironsides

- Vessel Make

- 54' Bruce Roberts steel sailboat hull, coastal LRC, 220HP CAT 3306.

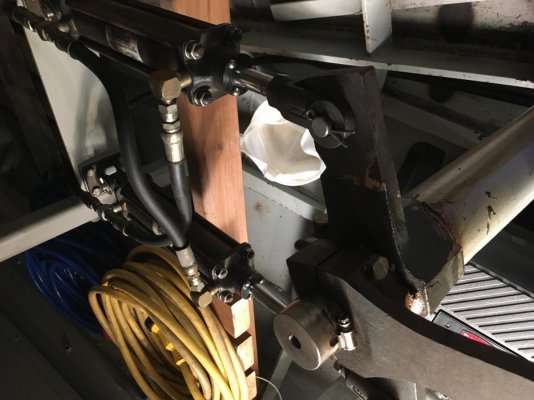

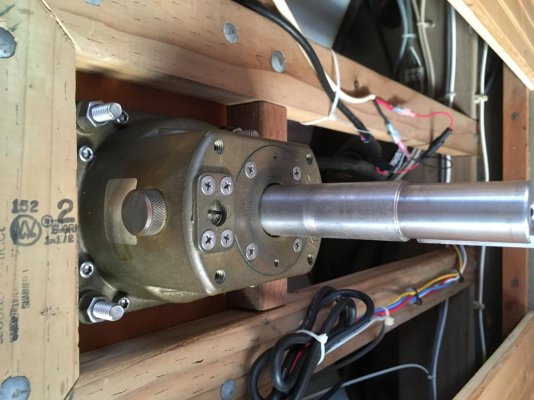

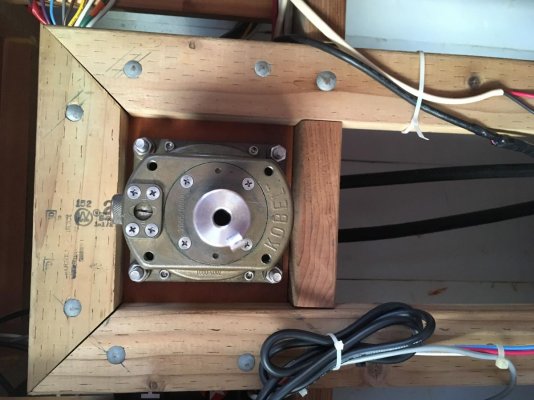

Can all these be installed in one package? I have a hydraulic steering system, which works, but very hard to steer. I do not have rudder indicator, nor autopilot.

It would be nice to have them all, but the autopilot can wait. Unless, there is a nice solution for all of these?

I certainly need the rudder indicator. The steering wheel is huge, possibly for sailboats. I have motorboat.

Anyone have an opinion on my needs, perhaps recommend a solution? One by one, or all at once to save money?

See photos.

It would be nice to have them all, but the autopilot can wait. Unless, there is a nice solution for all of these?

I certainly need the rudder indicator. The steering wheel is huge, possibly for sailboats. I have motorboat.

Anyone have an opinion on my needs, perhaps recommend a solution? One by one, or all at once to save money?

See photos.

Attachments

-

IMG_2543.jpg114.6 KB · Views: 164

IMG_2543.jpg114.6 KB · Views: 164 -

IMG_2544.jpg112.2 KB · Views: 150

IMG_2544.jpg112.2 KB · Views: 150 -

IMG_2551.jpg102.3 KB · Views: 147

IMG_2551.jpg102.3 KB · Views: 147 -

IMG_2552.jpg114.5 KB · Views: 174

IMG_2552.jpg114.5 KB · Views: 174 -

IMG_2548.jpg113.8 KB · Views: 149

IMG_2548.jpg113.8 KB · Views: 149 -

IMG_2550.jpg152.7 KB · Views: 142

IMG_2550.jpg152.7 KB · Views: 142 -

IMG_2547.jpg118.8 KB · Views: 150

IMG_2547.jpg118.8 KB · Views: 150 -

IMG_2545.jpg81.5 KB · Views: 143

IMG_2545.jpg81.5 KB · Views: 143 -

IMG_2546.jpg116.5 KB · Views: 137

IMG_2546.jpg116.5 KB · Views: 137 -

IMG_2553.jpg116.4 KB · Views: 133

IMG_2553.jpg116.4 KB · Views: 133