When last we heard, you were going to stop work and go on vacation for 5 days.

No I said I go in 5 days for 2 weeks. Leave Friday

When last we heard, you were going to stop work and go on vacation for 5 days.

Substantial work station with tables you have there. That at your job?

Wrap it up!

Damn, Matt - that stitching looks great. You're hired!!

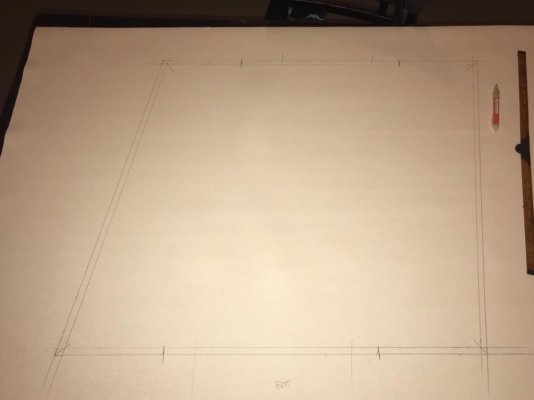

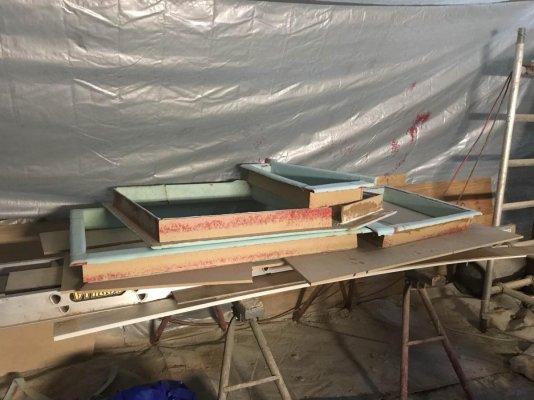

Only had 1 hour to spend at the boat today and that all that was needed to finish applying the foam to the last two window shrouds. I’ll bring them home tomorrow and set them aside for when I return from holidays and begin making tamplates so I can begin sewing French seams on the routered faced edge with my sewing machine. The leather covers are going to look great.

View attachment 79497

View attachment 79498

As long as I was doing upholstery, I never heard those stitches called French. We called them a double fold or parallel.

Joy Francis, Rex`s wife, must be elsewhere. We met her at a Sydney Boat Show along with Rex. I have a vague recollection there is a son who works in manufacturing. Impressive that a small specialized anchor design and manufacturer in Melbourne is exporting anchors to Canada(and probably elsewhere), as well as serving the Australia with world class anchors.

Is there anything that you don't master? Impressive skills you have!

L

Dunno about that mate. I couldn’t have made it without a little help from YouTube, google and the sailrite videos. With the right tools anyone can make anything if they want to.

More darn good work ... me Mate!

Operative phrase/word is in bold above!!

Excellent work on those covers and the trim panels. With the skills you're building while building and finishing your boat, you should never be without fall back work. When I was in the upholstery business, just covering those trim panels would have been around $100US each and that was back in the 90's.

Excellent work on those covers and the trim panels. With the skills you're building while building and finishing your boat, you should never be without fall back work. When I was in the upholstery business, just covering those trim panels would have been around $100US each and that was back in the 90's.

Awsome awesome awesome. ..walking foot machine? What material you using? Are you concerned about the foam backing failing or degrading?

I do have a billion questions for you master...lol

Few at a time...lol