Westiculo

Senior Member

- Joined

- Feb 27, 2017

- Messages

- 271

- Location

- US

- Vessel Name

- Rose Mary

- Vessel Make

- 42 Grand Banks Motoryacht - 1985

Thought I might post for a project I started on, windows for my GB42.

Making your own windows does not sound like the path of least resistance but a perfect storm of problems with my current GB windows (the aluminum model) combined with a lack of proper replacement options made me start this journey.

PROBLEMS WITH THE CURRENT WINDOWS:

My current windows are the aluminum version with laminated glass. The glass is permanently etched, I have 5 broken panes, the edge pile trim is shot where it's supposed to seal against the sliding pane, and 80% of the panes have condensation between the laminate layers. The frames themselves have the paint peeling off, galvanic corrosion where the snaps were installed, all need to be re-bedded, and all desperately need new tracks. It would require significant effort to remove the paint, scrape off the old silicone and repair all the areas where the stainless snaps turned the aluminum to dust; the only reasonable way forward here is a sandblaster - doable, but expensive. The other problem - and this is well addressed on the GB forum - is that the slot for putting new track in GBs aluminum models is too narrow to fit the standard stanpro track, making sourcing new track incredibly difficult.

PROBLEMS WITH COMMERCIALLY-AVAILABLE REPLACEMENT WINDOWS:

Most replacement windows are aluminum. On the offset, this is a problem because I live in Boston. Condensation on the window frames in the winter causes the same problems as clogged weep-holes for the window tracks. Regardless, I would have chosen this option if there were any attractive offerings. In my opinion, most of the new models retract from the look of a classic boat and are very expensive.

MY OWN DESIGN:

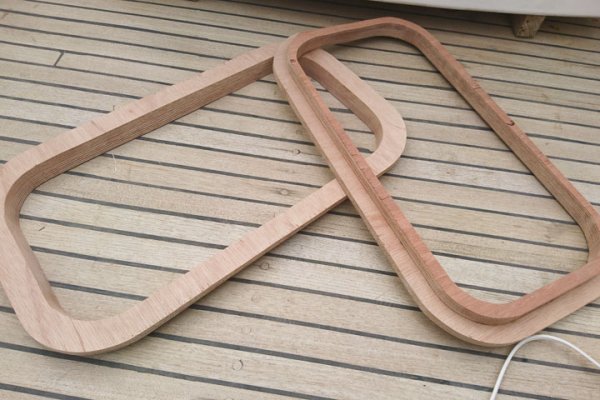

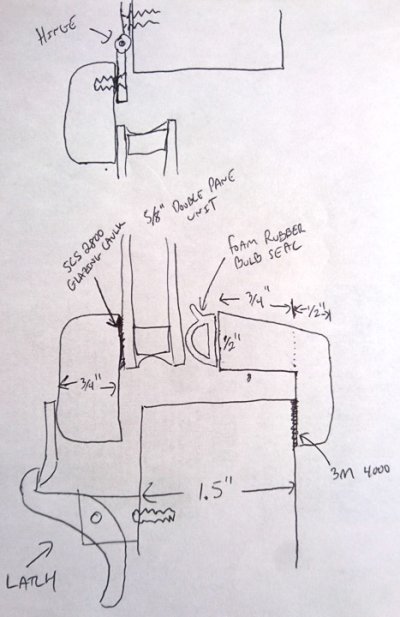

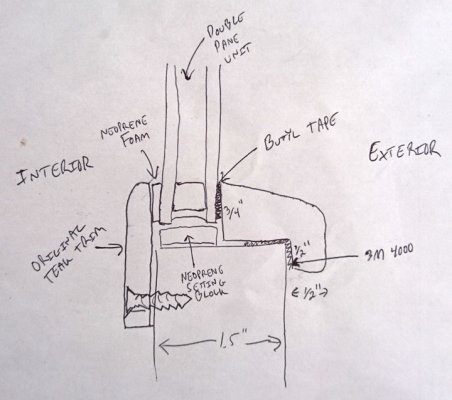

My windows are constructed from marine mahogany ply with a coat of epoxy followed by thickened epoxy, awlgrip primer, and awlgrip. I used ply because the window frames could be cut from a single piece of wood, making them stronger and simpler to build with round corners. The glass itself is double pane tempered with a low-e coating made by OneDayGlass (the same company as Motion Windows). I got rid of all sliding windows. All opening windows are awning (like portlights) and the large windows on the side of the salon are fixed. There are awning windows in the salon that will open outward in the windshield and aft-facing window. The pics here show the start and end results and the design. I'll post a few more of construction below.

Making your own windows does not sound like the path of least resistance but a perfect storm of problems with my current GB windows (the aluminum model) combined with a lack of proper replacement options made me start this journey.

PROBLEMS WITH THE CURRENT WINDOWS:

My current windows are the aluminum version with laminated glass. The glass is permanently etched, I have 5 broken panes, the edge pile trim is shot where it's supposed to seal against the sliding pane, and 80% of the panes have condensation between the laminate layers. The frames themselves have the paint peeling off, galvanic corrosion where the snaps were installed, all need to be re-bedded, and all desperately need new tracks. It would require significant effort to remove the paint, scrape off the old silicone and repair all the areas where the stainless snaps turned the aluminum to dust; the only reasonable way forward here is a sandblaster - doable, but expensive. The other problem - and this is well addressed on the GB forum - is that the slot for putting new track in GBs aluminum models is too narrow to fit the standard stanpro track, making sourcing new track incredibly difficult.

PROBLEMS WITH COMMERCIALLY-AVAILABLE REPLACEMENT WINDOWS:

Most replacement windows are aluminum. On the offset, this is a problem because I live in Boston. Condensation on the window frames in the winter causes the same problems as clogged weep-holes for the window tracks. Regardless, I would have chosen this option if there were any attractive offerings. In my opinion, most of the new models retract from the look of a classic boat and are very expensive.

MY OWN DESIGN:

My windows are constructed from marine mahogany ply with a coat of epoxy followed by thickened epoxy, awlgrip primer, and awlgrip. I used ply because the window frames could be cut from a single piece of wood, making them stronger and simpler to build with round corners. The glass itself is double pane tempered with a low-e coating made by OneDayGlass (the same company as Motion Windows). I got rid of all sliding windows. All opening windows are awning (like portlights) and the large windows on the side of the salon are fixed. There are awning windows in the salon that will open outward in the windshield and aft-facing window. The pics here show the start and end results and the design. I'll post a few more of construction below.

Attachments

-

Original Frame.jpg80.8 KB · Views: 130

Original Frame.jpg80.8 KB · Views: 130 -

Opening Design.jpg82.6 KB · Views: 134

Opening Design.jpg82.6 KB · Views: 134 -

Fixed Design.jpg78.6 KB · Views: 148

Fixed Design.jpg78.6 KB · Views: 148 -

Final Product.jpg95.7 KB · Views: 150

Final Product.jpg95.7 KB · Views: 150 -

First aft window installed.jpg74.5 KB · Views: 139

First aft window installed.jpg74.5 KB · Views: 139 -

Installed Corner.jpg88.7 KB · Views: 132

Installed Corner.jpg88.7 KB · Views: 132 -

Open.jpg99.4 KB · Views: 137

Open.jpg99.4 KB · Views: 137 -

Window Held Open.jpg98.9 KB · Views: 136

Window Held Open.jpg98.9 KB · Views: 136 -

Closed.jpg88.6 KB · Views: 133

Closed.jpg88.6 KB · Views: 133 -

Holder Open Latch.jpg96.1 KB · Views: 140

Holder Open Latch.jpg96.1 KB · Views: 140