Eddieandgail

Veteran Member

I have 1987 Lehman 135s with 2:1 velvet drives with 2500 hours. Port tranny filled with water 18 months ago when cooler went bad. Removed tranny, had it rebuilt at my trusted local tranny shop where owner said he did a couple a year of those without problem

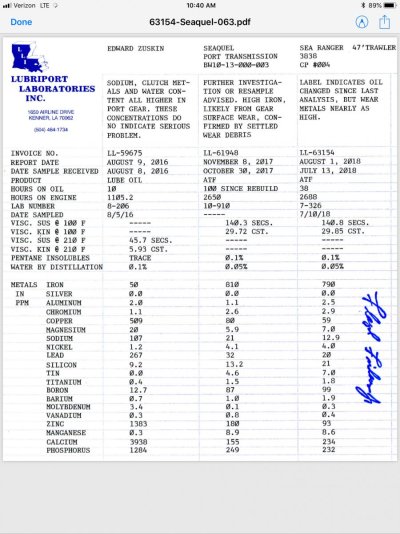

My first oil sample on rebuild at 100 hours showed 810 iron content

I changed the oil and My next one a couple weeks ago with 38 hours showed 790 so no better. Lab report believes gear wear and does show evidence of my recent oil change.

Runs smooth as silk no noises, shifts perfectly but can’t imagine what rebuilder could have done wrong.

Ideas please?

Eddie

47 Sea Ranger RPH

My first oil sample on rebuild at 100 hours showed 810 iron content

I changed the oil and My next one a couple weeks ago with 38 hours showed 790 so no better. Lab report believes gear wear and does show evidence of my recent oil change.

Runs smooth as silk no noises, shifts perfectly but can’t imagine what rebuilder could have done wrong.

Ideas please?

Eddie

47 Sea Ranger RPH