CaptFun

Member

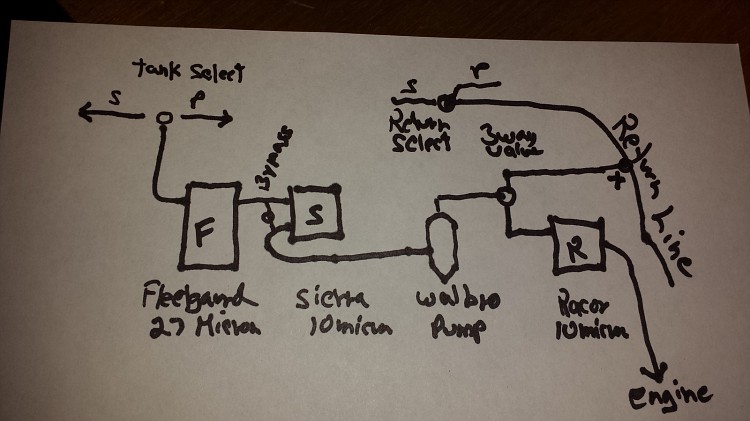

How would I go about setting up 2 Racors in series so if one plugs, I could switch a valve and run off the second filter. Small, hot, engine room.

I know Racor sells series set-ups, but they are north of $1000.

I know Racor sells series set-ups, but they are north of $1000.