wkearney99

Guru

- Joined

- Feb 17, 2018

- Messages

- 2,164

- Location

- USA

- Vessel Name

- Solstice

- Vessel Make

- Grand Banks 47 Eastbay FB

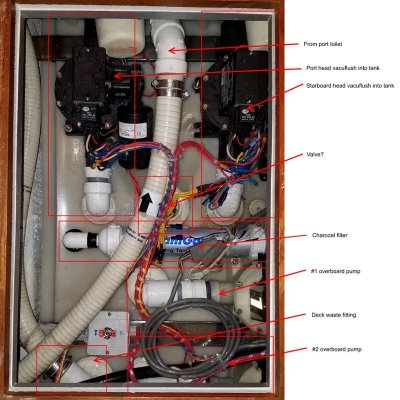

The holding tank on my Grand Banks Eastbay 47 has what looks like some sort of valve on it. The boat is 'new to me' so I'm getting used to how everything is set up. The owners manual makes no mention of the system details beyond hose diagrams.

After either of the vacuflush systems operates that valve on the holding tank is letting out air, which of course smells foul.

I've done nothing to the set up yet. The area looks wet because I was rinsing out the bilge area just aft of this (that has the sink/shower sumps) and splashed a bit of water up onto the holding setup. The moisture is not from within the tank itself. One of the shower sump pumps had failed and the tank had overflowed. That's been fixed and I was just rinsing out the bilge under it.

The system has has two vacuflush pumps leading to the tank. (one from each head, on separate breakers). The hose from each head goes into a small tank ahead of the pumps and then into the holding tank.

It has a charcoal filter mounted right to the top of the tank, screwed into an elbow. From the looks of things this hasn't been changed recently, not unless whoever replaced it also reattached various bit of the wiring back to it again using zip ties. I intend to correct this and keep the wires secured and free of the filter.

It also has two overboard discharge pumps. The overboard units are selectable using the toggle switch marked 1 & 2 on the junction box atop the tank. They're controlled by a keyed panel at the helm. I tested both of them while offshore during delivery from Rhode Island to Maryland and they worked fine. No zip tie on the through-hull, but it's on my list. If just to avoid giving anyone inspecting it a point to complain about it. We boat regularly in areas where we can't discharge, so this won't see regular use.

To try and find the source of the smell I poured a bit of dish soap on what looks like a flapper of some sort in the well of that valve. When I operate either of the vacuflush pumps and flush their respective head the soap on the valve bubbles up a bit. Which leads me to believe that's the source for the stink.

The previous owner was using West Marine's "PURE OCEANS Bio Odor Bioactive Head Treatment"

I'm assuming the charcoal filter needs to be changed and is probably not allowing effective airflow. I'm not keen on how close the filter is to the top of the tank as tilt from rising on plane and a full tank seems likely to allow it to get contaminated. I do not know if the overboard vent line is clear or not, but intend to check that also.

My question is what is that vent? And under what circumstances should or shouldn't it operate?

After either of the vacuflush systems operates that valve on the holding tank is letting out air, which of course smells foul.

I've done nothing to the set up yet. The area looks wet because I was rinsing out the bilge area just aft of this (that has the sink/shower sumps) and splashed a bit of water up onto the holding setup. The moisture is not from within the tank itself. One of the shower sump pumps had failed and the tank had overflowed. That's been fixed and I was just rinsing out the bilge under it.

The system has has two vacuflush pumps leading to the tank. (one from each head, on separate breakers). The hose from each head goes into a small tank ahead of the pumps and then into the holding tank.

It has a charcoal filter mounted right to the top of the tank, screwed into an elbow. From the looks of things this hasn't been changed recently, not unless whoever replaced it also reattached various bit of the wiring back to it again using zip ties. I intend to correct this and keep the wires secured and free of the filter.

It also has two overboard discharge pumps. The overboard units are selectable using the toggle switch marked 1 & 2 on the junction box atop the tank. They're controlled by a keyed panel at the helm. I tested both of them while offshore during delivery from Rhode Island to Maryland and they worked fine. No zip tie on the through-hull, but it's on my list. If just to avoid giving anyone inspecting it a point to complain about it. We boat regularly in areas where we can't discharge, so this won't see regular use.

To try and find the source of the smell I poured a bit of dish soap on what looks like a flapper of some sort in the well of that valve. When I operate either of the vacuflush pumps and flush their respective head the soap on the valve bubbles up a bit. Which leads me to believe that's the source for the stink.

The previous owner was using West Marine's "PURE OCEANS Bio Odor Bioactive Head Treatment"

I'm assuming the charcoal filter needs to be changed and is probably not allowing effective airflow. I'm not keen on how close the filter is to the top of the tank as tilt from rising on plane and a full tank seems likely to allow it to get contaminated. I do not know if the overboard vent line is clear or not, but intend to check that also.

My question is what is that vent? And under what circumstances should or shouldn't it operate?