Lou_tribal

Guru

Last year I got my steering cylinder rebuilt as it was leaking. Seals were changed, rod was polished clean and everything was fine.

After a winter on the ground I noticed again some leakage. This time it is not the cylinder itself but the fitting connection. The leak is very tiny, but after 6 month on the ground it was clearly noticeable.

My setup is as follow:

From the helm the line is copper.

Between the cylinder and the copper line there is around 1 foot of hose, quite stiff but less than the copper line.

Fitting on this hose, both side is compression fitting with olive/ferule. And this is where the leak is.

I am not sure if the fitting on the cylinder is NPSM or compression.

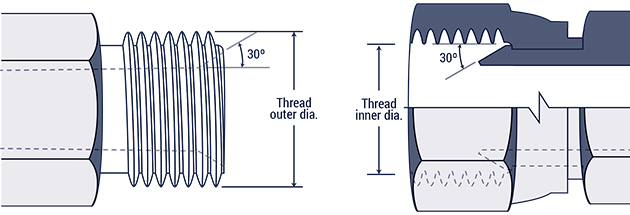

To illustrate what I mean here is NPSM fitting:

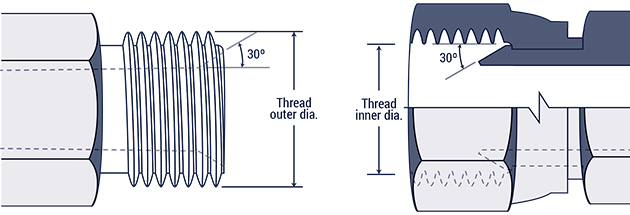

And compression:

https://www.hydraulicsdirect.com/v/vspfiles/assets/images/drawing_Flareless-Compression.jpg

So the questions...

First: Is compression fitting common for hydraulic? Is it the right thing?

Second: Any advice on getting this leak free?

Last: any recommendation on hose to be used? I found a lot of different hoses that could fit.

L

Se

After a winter on the ground I noticed again some leakage. This time it is not the cylinder itself but the fitting connection. The leak is very tiny, but after 6 month on the ground it was clearly noticeable.

My setup is as follow:

From the helm the line is copper.

Between the cylinder and the copper line there is around 1 foot of hose, quite stiff but less than the copper line.

Fitting on this hose, both side is compression fitting with olive/ferule. And this is where the leak is.

I am not sure if the fitting on the cylinder is NPSM or compression.

To illustrate what I mean here is NPSM fitting:

And compression:

https://www.hydraulicsdirect.com/v/vspfiles/assets/images/drawing_Flareless-Compression.jpg

So the questions...

First: Is compression fitting common for hydraulic? Is it the right thing?

Second: Any advice on getting this leak free?

Last: any recommendation on hose to be used? I found a lot of different hoses that could fit.

L

Se