Westiculo

Senior Member

- Joined

- Feb 27, 2017

- Messages

- 271

- Location

- US

- Vessel Name

- Rose Mary

- Vessel Make

- 42 Grand Banks Motoryacht - 1985

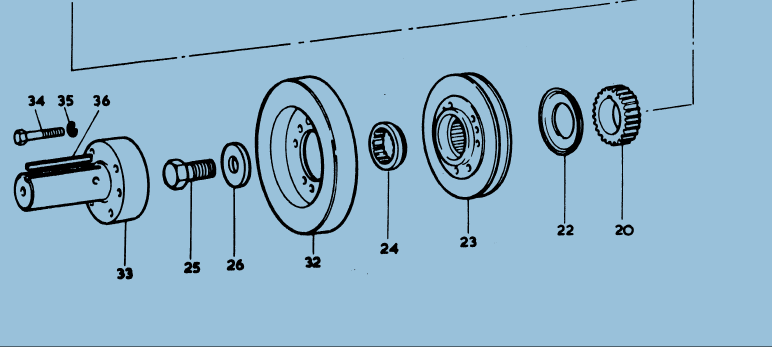

I have a twin engine, and on the starboard side I can grab the outside of the crankshaft pulley and slide it around the crankshaft bolt. Does this mean it's broken, or is this normal? I know for cars when your harmonic balancer slips, you need a new one. The port engine does not seem to do this, and the starboard side is also a bit wobbly. The center of the pulley pulley is not loose (the bolt is rock solid), just the outer part, indicating the rubber is cashed. These are Ford Lehman 135s.

Does this need to be replaced, if so, any good ideas on how to remove the bolt? I tried cranking on it - no dice. Also tried cranking the starter for an instant with a wrench on it, no dice... (as a side note, I drained all the oil from the engine, is there any problem with trying this again, or is it bad to crank it once or twice without oil? I don't want to refill, because I might replace the crankshaft seal in the timing cover if I have to pull the pulley)

Also, I almost always follow the rule that if something goes bad on one engine, replace it on the other, but $400 just for the part.... What do you guys think, will the 35-year-old rubber be kaput on the port-side engine too?

Does this need to be replaced, if so, any good ideas on how to remove the bolt? I tried cranking on it - no dice. Also tried cranking the starter for an instant with a wrench on it, no dice... (as a side note, I drained all the oil from the engine, is there any problem with trying this again, or is it bad to crank it once or twice without oil? I don't want to refill, because I might replace the crankshaft seal in the timing cover if I have to pull the pulley)

Also, I almost always follow the rule that if something goes bad on one engine, replace it on the other, but $400 just for the part.... What do you guys think, will the 35-year-old rubber be kaput on the port-side engine too?