RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

*THOSE 2-strokes are the most efficient engines on the planet, not 2-strokes in general.nomadwilly wrote:

"2 stroke engines are the most efficient engines on the planet"

What kind of scavenging systems are employed on those monster 2 strokes Rick?

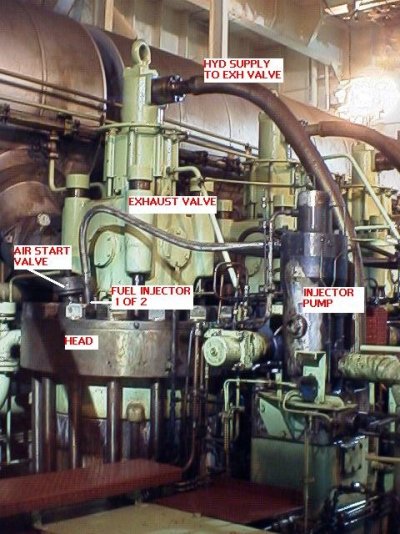

They are valve uniflow. The turbocharger discharges into a large (walk-in on larger engines) manifold that opens into the scavenge space.

A single hydraulically operated exhaust valve at the top of the cylinder opens as the piston nears the bottom of the stroke.* Circumferential slots near the bottom of the cylinder allow air to enter when the piston clears them on the way down after the exhaust valve opens. Fresh air washes the exhaust gases out of the cylinder, the valve closes, the piston moves up and compresses the charge after it passes and closes off the ports.

Benn mentioned the cylinder oil. It is delivered by a separate pump to ports drilled through the liner that feed grooves to distribute a special high base number cylinder oil to lubricate the piston. There just isn't any other way to lube the piston since it is not in common with the crankcase, plus a few other major reasons that would take up too much space here to talk about.

Since not all the cylinder oil burns away, some poor junior engineer has to crawl in the scavenge space to muck out the sludge that collects around the packing gland where the piston rod enters the space.

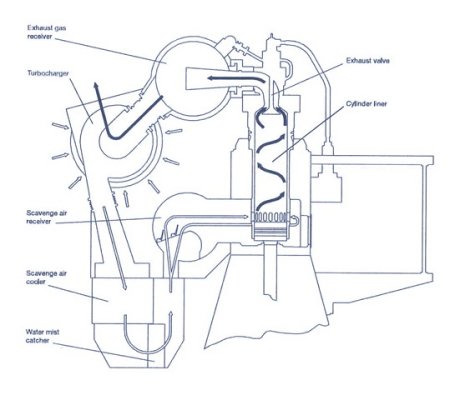

The line drawing shows the gas flow through the engine. The stuff between the turbo and the scavenge space is a charge air cooler and mist eliminator then the scavenge air manifold itself.

The first picture shows a view inside the "intake manifold" looking toward the far end where there is another access door. The boxy looking bit on the lower left is a set of check valves that allow using an electric blower to supply air when starting. The openings on the right are where air goes into the scavenge space. If I had turned the camera a bit more to the right you would see the cylinder and the slots where Benn talked about inspecting the rings.

The next picture shows the top of the engine with labels.

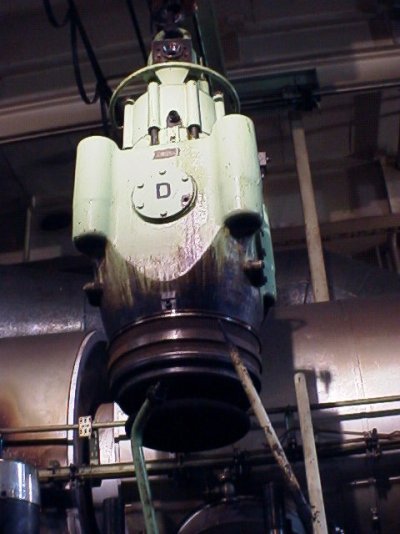

Next is an exhaust valve being removed for service and inspection. Note the valve itself is hanging open. Air pressure keeps it closed rather than a spring. That air is called "spring air" of course.

Next is the valve after being removed from its house. The angled vanes are there to use energy in the exhaust gas to rotate the valve so it self cleans carbon and crud from seating surfaces. The smiling gentleman is a warranty tech from Denmark who was there to inspect the parts as much of this was a warranty job rather than unplanned maintenance.