Lou_tribal

Guru

My fellows TFers, greetings from the frozen land.

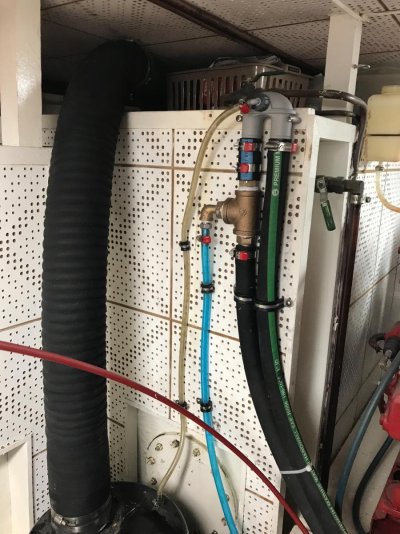

This morning I was curing my lack of boat by reading some docs from vetus. I have a waterlock from vetus on my exhaust line. In their doc they mention that an anti siphon valve should be set on the water line at a minimum of 40cm above the waterline. My exhaust water injection point is at the water level or few cm above and my ER does not allow to have an anti siphon valve at the mentioned level.

So the following questions

Is it required (or best) to have an anti siphon on the water injection line?

If yes what do you think about the 40cm?

How about the waterlock setup?

Note: my setup has a flap on the exhaust to avoid water ingress, a 1 to 1.5 feet rise before the exhaust output and the waterlock 1 foot below the exhaust from manifold. Never had an issue cruising in fresh water but thinking about this (or over thinking about this )in sea waves.

L

This morning I was curing my lack of boat by reading some docs from vetus. I have a waterlock from vetus on my exhaust line. In their doc they mention that an anti siphon valve should be set on the water line at a minimum of 40cm above the waterline. My exhaust water injection point is at the water level or few cm above and my ER does not allow to have an anti siphon valve at the mentioned level.

So the following questions

Is it required (or best) to have an anti siphon on the water injection line?

If yes what do you think about the 40cm?

How about the waterlock setup?

Note: my setup has a flap on the exhaust to avoid water ingress, a 1 to 1.5 feet rise before the exhaust output and the waterlock 1 foot below the exhaust from manifold. Never had an issue cruising in fresh water but thinking about this (or over thinking about this )in sea waves.

L