FBoykin

Senior Member

- Joined

- Feb 13, 2014

- Messages

- 165

- Vessel Name

- Hannah Jane

- Vessel Make

- 2000 Grand Banks 42 Classic

Hi All, I'm about to tackle re-grooving the teak deck seams on a new-to-me GB 42 I bought in Oct. 2015. There are plenty of posts here and on the Grand Banks Owners site and I'm reading all I can. For now I'm trying to find some details on using the small Makita battery powered saw to deepen the seams. I'm hoping some folks can help me out.

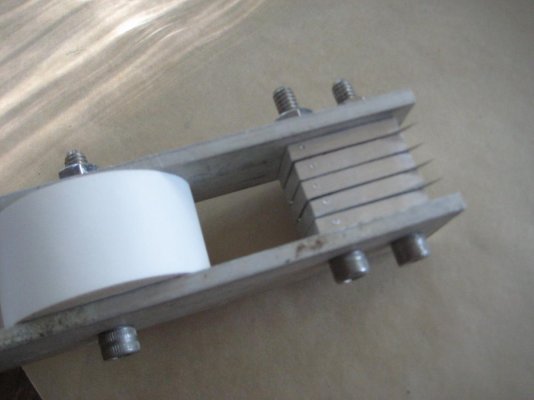

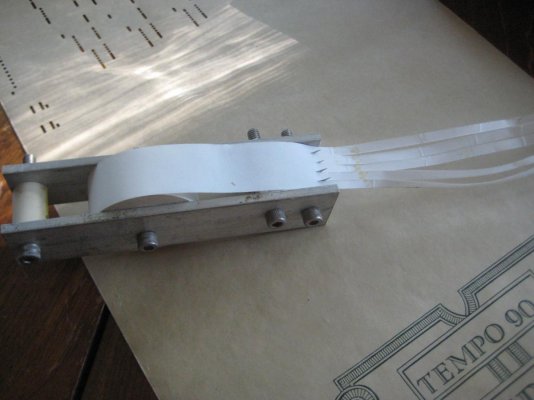

I've seen posts on making a shoe for the saw and adding a 1/4 bolt or nylon dowel at the back end to use as a guide pin. Folks also talk about stacking multiple blades to cut a wider groove (1/4" width).

My questions (which I've also posted on the GB site) are:

How many teeth on the blade (regular cut vs fine cut, etc.)?

What kind of spacers to use?

Any tricks to stacking the blades besides making sure the teeth are offset? I believe you also have to remove the blade guard too.

Is the need for a "shoe" just to create a surface to attach the guide pin to?

Any details on what to make the shoe out of (plywood, lexan, etc.) and how big to make it? Same size as the saw base, etc.?

Luckily the Teak Decking Systems factory is on my drive to my boat - I've visited and talked w/them numerous times and bought their tools and caulk. Good folks.

Any tips or guidance on using the Makita to do the seams would be greatly appreciated. Thanks!

I've seen posts on making a shoe for the saw and adding a 1/4 bolt or nylon dowel at the back end to use as a guide pin. Folks also talk about stacking multiple blades to cut a wider groove (1/4" width).

My questions (which I've also posted on the GB site) are:

How many teeth on the blade (regular cut vs fine cut, etc.)?

What kind of spacers to use?

Any tricks to stacking the blades besides making sure the teeth are offset? I believe you also have to remove the blade guard too.

Is the need for a "shoe" just to create a surface to attach the guide pin to?

Any details on what to make the shoe out of (plywood, lexan, etc.) and how big to make it? Same size as the saw base, etc.?

Luckily the Teak Decking Systems factory is on my drive to my boat - I've visited and talked w/them numerous times and bought their tools and caulk. Good folks.

Any tips or guidance on using the Makita to do the seams would be greatly appreciated. Thanks!