Tony B

Guru

- Joined

- Jul 18, 2011

- Messages

- 1,251

- Location

- Cruising/Live-Aboard USA

- Vessel Name

- Serenity

- Vessel Make

- Mainship 36 Dual Cabin -1986

Here is the situation:

When offshore last, the macerator quit working. I hear the motor running but nothing is going anywhere.

We switched the potty to direct overboard when out there and I think it was still going in the tank but no way of knowing.

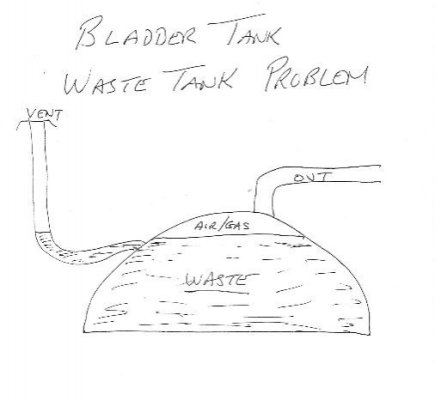

When we got back to the dock, we have a dockside pumpout barge come by and empty the tank for us. Well.....it starts to suck for about 3 to 5 seconds and then quits. It sounds like air or something is in a line or something but I dont know what is wrong.

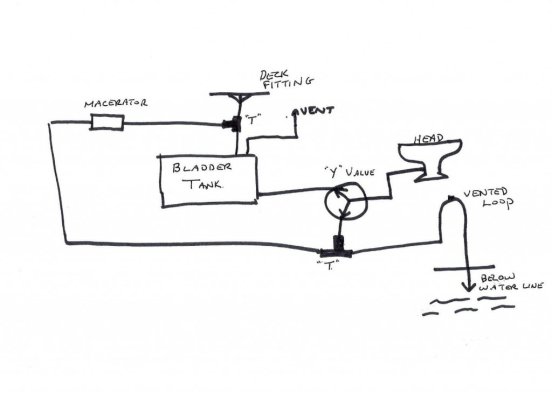

Attached is a sketch I made of the system from what*I could get my wife to describe over the phone. I'm not sure if this sketch is accurate and I wont know till I get home.

All I know is that when I get home I got to put up with a lot of s**t.

Thanks in advance.

When offshore last, the macerator quit working. I hear the motor running but nothing is going anywhere.

We switched the potty to direct overboard when out there and I think it was still going in the tank but no way of knowing.

When we got back to the dock, we have a dockside pumpout barge come by and empty the tank for us. Well.....it starts to suck for about 3 to 5 seconds and then quits. It sounds like air or something is in a line or something but I dont know what is wrong.

Attached is a sketch I made of the system from what*I could get my wife to describe over the phone. I'm not sure if this sketch is accurate and I wont know till I get home.

All I know is that when I get home I got to put up with a lot of s**t.

Thanks in advance.