You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Belts

- Thread starter rbwetta

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

psneeld

Guru

Only 4 things on the tip of my tongue....

1. Broken bracket or bolts...happened to me last year and took a couple days till obvious enough that the bracket was cocking the alternator in addition to loose belts.

2. You are tightening them too much to begin with.

3. They are still new and stetching normally.

4. Wrong size for the groove and/or they are wearing fast and pulling too deep into groove.

1. Broken bracket or bolts...happened to me last year and took a couple days till obvious enough that the bracket was cocking the alternator in addition to loose belts.

2. You are tightening them too much to begin with.

3. They are still new and stetching normally.

4. Wrong size for the groove and/or they are wearing fast and pulling too deep into groove.

Last edited:

diver dave

Guru

- Joined

- Jan 13, 2017

- Messages

- 2,570

- Location

- United States

- Vessel Name

- Coquina

- Vessel Make

- Lagoon 380

If there is associated rubber dust, then pulley corrosion or alignment are typical culprits. If no dusting, then lets hear what the mechanic has to say.

rbwetta

Member

- Joined

- Jul 20, 2017

- Messages

- 10

- Location

- USA

- Vessel Name

- Corporate Office

- Vessel Make

- Ocean Alexander 42 Altus

If there is associated rubber dust, then pulley corrosion or alignment are typical culprits. If no dusting, then lets hear what the mechanic has to say.

Always find rubber dust. I would estimate 10 hours on the new belts. It seems the fasteners on the tensioning brackets are backing off. Locking bolt head is a bit worn and rounded so I suspect this has been an ongoing problem and someone used the wrong tools. I’ve only owned the boat for about 2 months. Thanks for the replies and I will reply back with what the mechanic says. Also just purchased a belt tensioning jack to make this a bit easier.

RT Firefly

Enigma

Greetings,

Mr. rb. One of our members (Of course I can't remember who...) incorporated a turnbuckle into the accessory mounting/adjustment mechanism. I, myself, have done this with the alternator on a 350 Mercruiser and it works marvelously.

I removed the original slotted upper bracket and mounted a SS turnbuckle in it's place. MY problem was the lower mounting hole on the alternator had worn oval causing the alternator to skew and be misaligned with the drive pulley...meaning increased wear AND inability to keep the V-belt consistently tight.

I had to drill out that hole and press in a sleeve.

Edit: It could be Mr. OC Diver did this to his engine...

Mr. rb. One of our members (Of course I can't remember who...) incorporated a turnbuckle into the accessory mounting/adjustment mechanism. I, myself, have done this with the alternator on a 350 Mercruiser and it works marvelously.

I removed the original slotted upper bracket and mounted a SS turnbuckle in it's place. MY problem was the lower mounting hole on the alternator had worn oval causing the alternator to skew and be misaligned with the drive pulley...meaning increased wear AND inability to keep the V-belt consistently tight.

I had to drill out that hole and press in a sleeve.

Edit: It could be Mr. OC Diver did this to his engine...

Last edited:

stubones99

Guru

Gates has some interesting videos about belt problems that may help. You didn't say whether it was a single V, pair of belts, or serpentine belt..

All V belts wear a bit initially and need adjustment regularly as they seat themselves on the sheaves. Every day, check the deflection and adjust as necessary. You should find the wear will drop as they seat on the sheaves.

All V belts wear a bit initially and need adjustment regularly as they seat themselves on the sheaves. Every day, check the deflection and adjust as necessary. You should find the wear will drop as they seat on the sheaves.

kchace

Guru

- Joined

- Sep 29, 2013

- Messages

- 2,265

- Location

- USA

- Vessel Name

- Shalloway

- Vessel Make

- Defever 44, twin Perkins

If you're getting belt dust in that short a time then something is wearing the belts abnormally. The most likely cause is roughness on one or more of the pulleys. All pulleys should be absolutely smooth where they make contact with the belts.

Ken

Ken

av8r

Senior Member

After seeing the pic RT refers to I installed a March turnbuckle, aka "adjustable alternator bracket" for my Ample alternator on a Lehman 120. Gates makes a small tension gage that is easy to use and the turnbuckle lets you actually adjust the belt instead of hoping it's close when you crank down the bolt.

And it looks cool.

And it looks cool.

rbwetta

Member

- Joined

- Jul 20, 2017

- Messages

- 10

- Location

- USA

- Vessel Name

- Corporate Office

- Vessel Make

- Ocean Alexander 42 Altus

After seeing the pic RT refers to I installed a March turnbuckle, aka "adjustable alternator bracket" for my Ample alternator on a Lehman 120. Gates makes a small tension gage that is easy to use and the turnbuckle lets you actually adjust the belt instead of hoping it's close when you crank down the bolt.

And it looks cool.

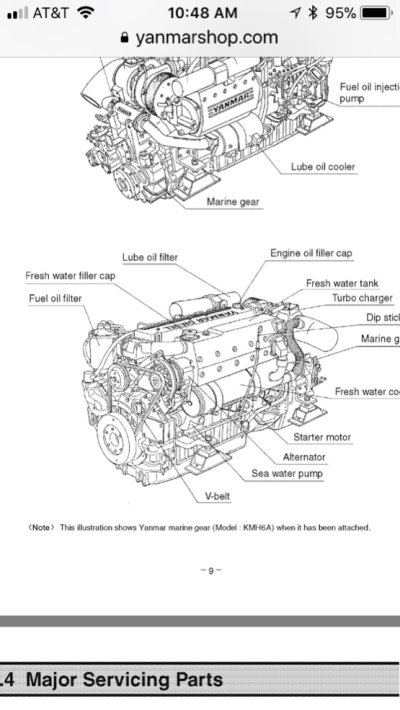

It’s a single V belt. I have twin 440HP Yanmar’s and seem to have the issue on both engines. I read where I should lightly sand the pulleys so I assume this will keep them smooth. Again - thanks for all the suggestions.

Ski in NC

Technical Guru

Those Yanmar 6LY series are belt eaters. I think the fwd end of the crank is lively with torsional activity and that is hard on the belts. Worse at higher power settings. Make sure pulleys have NO rust on them and tighten as needed. Use good quality belts and maybe try different brands. Some will wear slower than others.

Nomad Willy

Guru

If things are aligned well and the load on the belt is low they should last a long time. My seawater drive belt is relatively loose and dosn’t slip. It’s not been exposed to fuel or other agressive fluids. That belt on my boat has been there for over 10yrs and shows no sign of weakness.

Many people just feel better replacing things like belts. I replace my lube oil over twice a year and would like to replace my fuel (in the usual manner) more than that. Perhaps this year.

Many people just feel better replacing things like belts. I replace my lube oil over twice a year and would like to replace my fuel (in the usual manner) more than that. Perhaps this year.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

BEWARE!

If the alt has a better 3 stage regulator a single belt will be highly loaded.

This can cause the alt belt to slip at the alt pulley , which makes it run hot.

So hot the bearings can melt the grease and the alt will sieze.

Use a thermometer gun to observe what is hot.,

If the alt has a better 3 stage regulator a single belt will be highly loaded.

This can cause the alt belt to slip at the alt pulley , which makes it run hot.

So hot the bearings can melt the grease and the alt will sieze.

Use a thermometer gun to observe what is hot.,

cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

BEWARE!

If the alt has a better 3 stage regulator a single belt will be highly loaded.

This can cause the alt belt to slip at the alt pulley , which makes it run hot.

So hot the bearings can melt the grease and the alt will sieze.

Use a thermometer gun to observe what is hot.,

I have a fancy Balmar regulator and I’m always replacing belts. Tons of belt dust. What’s the right temp for an alternator and belt ?

johnma

Guru

make sure you are using Yanmar's belts. I have a 6LY 370 series and threw a belt. Took it to my local auto parts shop for a replacement. The one they had was close but not close enough and loosened up pretty quickly. I bit the bullet and bought a new Yanmar belt for about 5x the cost of the aftermarket. when I compared the new Yanmar with a new aftermarket they were not even close. Have had no issues with the new Yanmar. 84 hours so far.

John

John

High Wire

Guru

I found I was not tightened enough. With the engine off grab the alt fan and turn by hand both directions. If you can move it you are too loose. Now I can drive 100 amps at low rpm with out slipping. 3/8” deflection between largest separated pulleys.

Last edited:

Similar threads

- Replies

- 15

- Views

- 2K