I have three large deck hatches over the engine room. They are heavy and difficult to handle and remove safely unless you have a helper. Has anyone hinged these large hatches to make it safer to open them ? Any and all ideas for hinging them and type of hinges used appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Manatee Engine Hatches

- Thread starter HiDHo

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Dave_E

Senior Member

While the idea is novel, the practicality might be otherwise. You could establish hinges (don't see a real issue there), but if you had to remove the hatches, now you really humping some heavy, awkward pieces of bulk that would require two people.

If this were practical... it would have been done long ago I think.

Dave

If this were practical... it would have been done long ago I think.

Dave

Duvie

Senior Member

- Joined

- Nov 5, 2011

- Messages

- 341

Make them lighter

My hatches were very heavy when I purchase my Californian. I made them lighter by installing a removable aluminum strut in the center where the two hatches meet up. This allowed me to remove all the structural materials off the old hatch. Now my hatches are basically a piece of plywood with carpet on them. One of the best things I ever did on the boat. Have pictures of the aluminum strut and socket in the link.

http://www.trawlerforum.com/forums/s24/salon-floor-4767.html

My hatches were very heavy when I purchase my Californian. I made them lighter by installing a removable aluminum strut in the center where the two hatches meet up. This allowed me to remove all the structural materials off the old hatch. Now my hatches are basically a piece of plywood with carpet on them. One of the best things I ever did on the boat. Have pictures of the aluminum strut and socket in the link.

http://www.trawlerforum.com/forums/s24/salon-floor-4767.html

It looks like our hatches could be twins.  . I hinged the aft hatch and added gas/spring struts. Trying to figure our the strut was hard and I don’t think I have it quite right, almost though. I could go a little heavier maybe. The hatch stays up on it’s own without resting against the door frame. The struts make it much easier to lift. The hinge is a standard 1” piano hinge. If you need any specifics let me know.

. I hinged the aft hatch and added gas/spring struts. Trying to figure our the strut was hard and I don’t think I have it quite right, almost though. I could go a little heavier maybe. The hatch stays up on it’s own without resting against the door frame. The struts make it much easier to lift. The hinge is a standard 1” piano hinge. If you need any specifics let me know.

Attachments

-

6419F0AC-DBEC-4EC7-8B8B-E7BCF157E0EF.jpg87.5 KB · Views: 150

6419F0AC-DBEC-4EC7-8B8B-E7BCF157E0EF.jpg87.5 KB · Views: 150 -

C81293D2-F7B0-4456-B9E4-8092D888D446.jpg107.1 KB · Views: 165

C81293D2-F7B0-4456-B9E4-8092D888D446.jpg107.1 KB · Views: 165 -

BED0CB7F-1B56-4026-9066-92542F7B845A.jpg100.2 KB · Views: 149

BED0CB7F-1B56-4026-9066-92542F7B845A.jpg100.2 KB · Views: 149 -

14A62960-EBCE-4F29-B8B6-9FAE74F99918.jpg111.2 KB · Views: 164

14A62960-EBCE-4F29-B8B6-9FAE74F99918.jpg111.2 KB · Views: 164 -

596B85BC-4F45-4B34-90CB-4CB5F66448A1.jpg128.5 KB · Views: 164

596B85BC-4F45-4B34-90CB-4CB5F66448A1.jpg128.5 KB · Views: 164 -

00854E2F-3B83-4D15-B4E1-7A309245E267.jpg58.6 KB · Views: 163

00854E2F-3B83-4D15-B4E1-7A309245E267.jpg58.6 KB · Views: 163

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

I’ve been hashing this over as well, Bill. Most tadical and effective solution I’ve seen yet is the Anderson’s Mango Mama. All three hatches drilled for pins, then glued together and with a gas assist. I’ll see if I can get a better picture. Of course, if you have a built-in settee like mine, you’ll need to relocate one of the table mounting stanchion bases. Only downside I see is checking sight tube for fuel tank.

Attachments

Last edited:

Interesting plan Larry. I think i might hinge them on the aft side. I have a built in settee but my table is mounted on a base plate with felt pads so I can slide it into any position. There’s a real safety plus in stabilizing them, I’ve had a few close calls reinstalling them and missing the edge they nest in, bad news hitting the engine top area. More photos would be great.

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Probably the main reason I haven’t done it yet is I still manage to handle them OK, and I cant decide which way to hinge them. If you hinge them aft, wouldn’t it block youe exit? What if they were hinged like a tri-fold door. They would slide easily on teflon rail toppers. Which hatch section do you remove most often. For me, the center one for oil & fuel filter checks. Being able to hinge that on the port side would make the easiest access. I check sight tubes for fuel with the most forward hatch. Again, tilting to port would be the most convenient, but the hatch has one of the two table mounting bases there. At the very least, I’ll need to change the table mount to something like yours. Maybe it’s time to do it.

Larry after seeing you re-engineer the transom door I will defer to any of your ideas. If money was no problem I’d tie all three together and install remote controled hydralic/electric powered hinges to open to starboard.

There’s a fairly new SeaRay Sundancer at our dock and a switch on the console opens the whole aft area over the engines and generator area so it can be done.

There’s a fairly new SeaRay Sundancer at our dock and a switch on the console opens the whole aft area over the engines and generator area so it can be done.

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Ok, so here is a better shot of the integrated engine hatches on Mangoo Mama. In addition to dowel pinning and gluing the three hatch covers together, Bob added a sheet of rubberized lead to reduce noise. I can only post one photo at a time from this I-Phone so the close up of the mating seam area will be in the next post.

Attachments

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Finally, Bob installed two assist gas shocks. Pulling the first foot or so takes some effort, but beyond that it takes itself up. The gas—assist shocks disconnect easily so the whole hatch can lay back on the fwd settee area. I asked Bob if he has found any regretson doing the design and he says “none”, but it’s apparent that the step in or out of the salon doors is awkward. I may decide to mate the front two and keep the aft most cover on a separate hinge. Still can’t decide which way to tilt toward.

Attachments

Last edited:

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Thanks Larry, I now have plenty of ideas on hinging my engine hatches. Like you I’m still working out on paper which method to use, I’m inclined to hinge them port or stbd. Researching piano hinges I was amazed at the various sizes available.

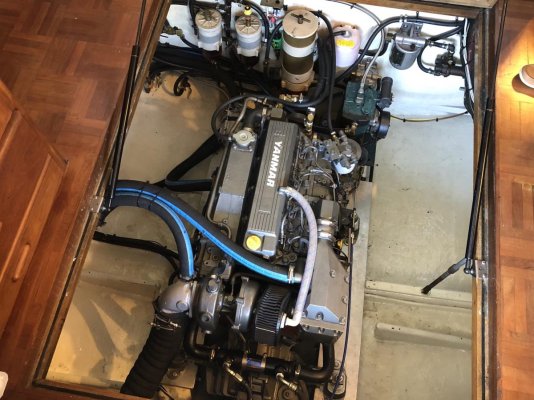

My Volvo TMD31A is still running great but good to know the Yanmar Bob installed fits nicely into the engine room.

Bill

My Volvo TMD31A is still running great but good to know the Yanmar Bob installed fits nicely into the engine room.

Bill

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

And if the integrated gas-assist engine hatch isn’t enough, check oit Mango Mama’s amidships galley hatch. Almost the entire sole opens for simple step down and in reach of machinery & tankage. Must be at least twice the size of mine.

Attachments

stubones99

Guru

You could use electric actuators instead of gas struts and do the remote control opening thing... gas struts always seem to have a short life, in my experience.

HeadedToTexas

Guru

It looks like our hatches could be twins.. I hinged the aft hatch and added gas/spring struts. Trying to figure our the strut was hard and I don’t think I have it quite right, almost though. I could go a little heavier maybe. The hatch stays up on it’s own without resting against the door frame. The struts make it much easier to lift. The hinge is a standard 1” piano hinge. If you need any specifics let me know.

Sorry to revive this old thread, but it is exactly what I am after. Very nice work, Larry. Did you have to inlet space for the piano hinge in your hatch in order for them to fit together in the floor recess?

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

He must have had to do that. The hatches on these Krogens fit pretty tight. Additionally, (due to the thickness), I wonder if he needed to bevel the edge of the opposite side a bit to keep the hatch from binding on its outer radius. I still haven’t gotten to this project yet, but I like the way Larry has done his.

It seems that hinging each hatch to operate independently may give the owner more options.

It seems that hinging each hatch to operate independently may give the owner more options.

Last edited:

HeadedToTexas

Guru

I only have three, and may hinge only two of them. The main engine opening in my pilothouse is covered by two separate, side by side hatches, but I usually remove only the forward hatch.

boathealer

Guru

I remade the hatch on our previous boat, an AT34.

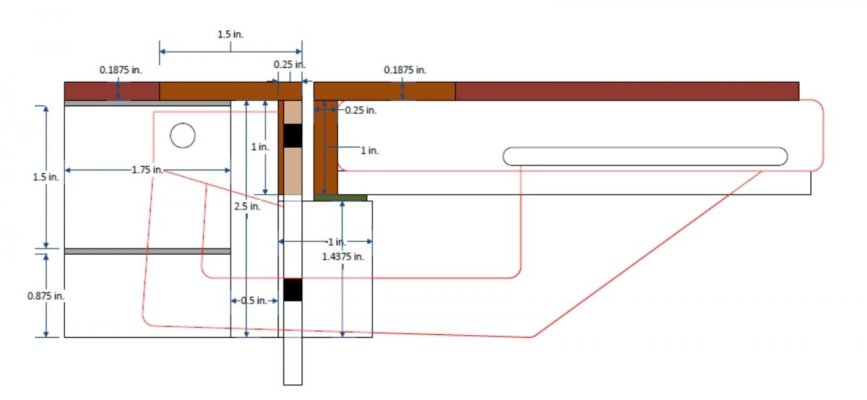

I chose some "up-and-out" hinges that required a TON of work - verifying on a CAD system to assure clearances. Then, dummy me decides curved corners would look really good - another 36 hours of work and complicated teak trim pieces.....

- another 36 hours of work and complicated teak trim pieces.....

A massive amount of work, but it sure looked good in the end. Probably wouldn't go through that much effort if I had to do it again.

I chose some "up-and-out" hinges that required a TON of work - verifying on a CAD system to assure clearances. Then, dummy me decides curved corners would look really good

A massive amount of work, but it sure looked good in the end. Probably wouldn't go through that much effort if I had to do it again.

Attachments

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

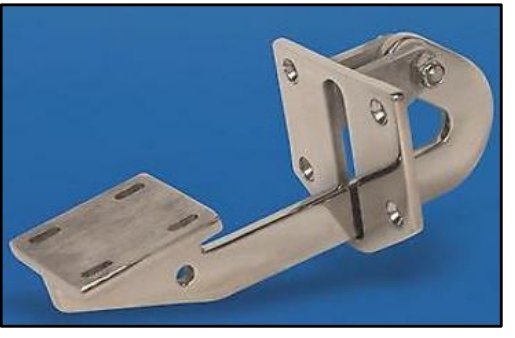

Healer: Been looking for those hinges. Were did you get them?

boathealer

Guru

Healer: Been looking for those hinges. Were did you get them?

Unfortunately, that was a while ago - I don't remember. Sorry.

I did find a picture in my documents, tho. Perhaps google photo search can find it?

EDIT: Found it - a bit "spendy", but very nicely put together.

https://www.summitracing.com/parts/...Hf-7d4zCF5Wx43MthlGv1sBw391yIBCxoCg_UQAvD_BwE

.

.

Attachments

Last edited:

HeadedToTexas

Guru

Wow, yes that is really slick. Great ideas executed with fine craftsman always feel worthwhile, at least once completed. Guessing your curved corner hatch is the same way. I really hope I find a way to simply add piano hinges and gas struts to my hatches with but small mods. Fingers are crossed!

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Healer: Can’t believe you found those. I just hacked off the lower edges of my perfect hatch to compensate for the swing radius needed for conventional hinges. I’ may be able to use the Summit examples if I can disassemble them and mount the base plates horizontally. Thanks.

Last edited:

boathealer

Guru

Healer: Can’t believe you found those. I just hacked off the lower edges of my perfect hatch to compensate for the swing radius needed for conventional hinges. I’ may be able to use the Summit examples if I can disassemble them and mount the base plates horizontally. Thanks.

I'm not sure the "throw" will allow them to be mounted that way. I would have wanted that, too, as I had to build out some small vertical blocks to hold the base.

Maybe you're seeing something I missed, though! (that happens to me a lot).

HeadedToTexas

Guru

I can tip my hatches up as if they were hinged. Hoping that means my piano hinge approach will work with a minimum of modification.

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

I can tip my hatches up as if they were hinged. Hoping that means my piano hinge approach will work with a minimum of modification.

Yes, If you already have the clearance to be able to tip the hatch up now, you probably won’t have any issues. The problem I have is a combo of the hatch fitting tight to the frame, and being 2.5” thick. No clearance for the hatch to naturally tilt as it raises on the hinge axis.

If I can find (or fabricate) the up & out hinge style that Boatpoker referenced, that would likely take care of the clearance issue. What boils me is that I have already ground down the edges of my perfect hatch to compensate for the interference.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

We had an F32 Trojan that had huge engine hatches that weighed more than I could easily lift and move. I put piano hinges on them and it made it simple and easy to lift them since they were controlled by the hinges and didn’t slip all over. I made some bungees to hold them in the open position.

HeadedToTexas

Guru

Inspiring news. Thanks guys. Sure am looking forward to some warmer weather. We splash on April 23rd.