Nomad Willy

Guru

Quote:

Originally Posted by Nomad Willy View Post

Some grinding took off the roll bar.

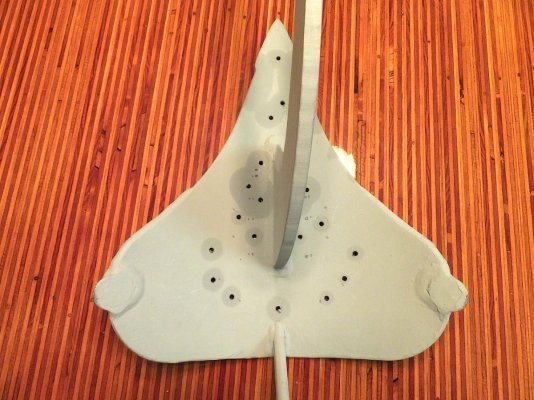

When I bought the Supreme it was advertised as a 15lb anchor. It weighed 18lbs. Now it weighs 15lbs. The roll bar was heavier than I though it would be. As a result the CG is considerably lower. The only way one can make it drag is to stand it up vertical and tip it backwards away from the fluke. Very unlikely for the anchor to end up vertical and as soon as one started to back down it would be on it's side. Should work but then it's anchoring and surprises abound.

I have another modification planned that should take the place of the roll bar and force the anchor to orient itself properly. Very little weight and drag.

I want to try it as seen in the pics before further modification. I don't want to add stuff and then want to come back where I was before. I'm going to use the little cable as seen in the last pic to help w the penetration. If it won't penetrate deeper that the stock anchor w the roll bar then my mod is pointless.

Attachment 38021

Attachment 38022

Attachment 38023

Attachment 38024

Attachment 38025

I was going to revive the thread but there's too much BS on it. Even arguing w Marin. Didn't realize it was that old.

In about a week we'll be going on our first cruise in some time. I plan to use the modified Supreme much of the time especially on questionable bottoms. Want to see if my substitute for the roll bar can provide dependable setting.

I included this old post (second pic (attachment) is best) to show how I've modified the anchor. The most recent mod was grinding (lots of grinding) the leading edge of the shank to a quite sharp knife like shape. The whole philosophy of this anchor mod is to attain a far less draggy substitute for the roll bar and streamline the other parts to permit low drag through the bottom and deeper penetration. But it needs to set dependably. Will report back.

The other anchor (XYZ) has been modified again since it's last been seen so I included two pics (after and before).

Attached Thumbnails

Click image for larger version

Originally Posted by Nomad Willy View Post

Some grinding took off the roll bar.

When I bought the Supreme it was advertised as a 15lb anchor. It weighed 18lbs. Now it weighs 15lbs. The roll bar was heavier than I though it would be. As a result the CG is considerably lower. The only way one can make it drag is to stand it up vertical and tip it backwards away from the fluke. Very unlikely for the anchor to end up vertical and as soon as one started to back down it would be on it's side. Should work but then it's anchoring and surprises abound.

I have another modification planned that should take the place of the roll bar and force the anchor to orient itself properly. Very little weight and drag.

I want to try it as seen in the pics before further modification. I don't want to add stuff and then want to come back where I was before. I'm going to use the little cable as seen in the last pic to help w the penetration. If it won't penetrate deeper that the stock anchor w the roll bar then my mod is pointless.

Attachment 38021

Attachment 38022

Attachment 38023

Attachment 38024

Attachment 38025

I was going to revive the thread but there's too much BS on it. Even arguing w Marin. Didn't realize it was that old.

In about a week we'll be going on our first cruise in some time. I plan to use the modified Supreme much of the time especially on questionable bottoms. Want to see if my substitute for the roll bar can provide dependable setting.

I included this old post (second pic (attachment) is best) to show how I've modified the anchor. The most recent mod was grinding (lots of grinding) the leading edge of the shank to a quite sharp knife like shape. The whole philosophy of this anchor mod is to attain a far less draggy substitute for the roll bar and streamline the other parts to permit low drag through the bottom and deeper penetration. But it needs to set dependably. Will report back.

The other anchor (XYZ) has been modified again since it's last been seen so I included two pics (after and before).

Attached Thumbnails

Click image for larger version

Attachments

Last edited: