Dave,

I've done this twice. The 1st time I installed with 5200, HUGE mistake. If you want, install the fairing with 5200, but the transducer should be bedded with polysulfide (Life-Caulk) Polysulfide cures underwater, it's not an adhesive, and it stays pliable so it makes an excellent beddding for thru-hull use. There's just no reason to use 5200 on stuff you may want to get apart as some future point.

Now, if your B744 was installed with 5200, then use this stuff to break the bond.

https://www.debondcorporation.com/products/marine-formula

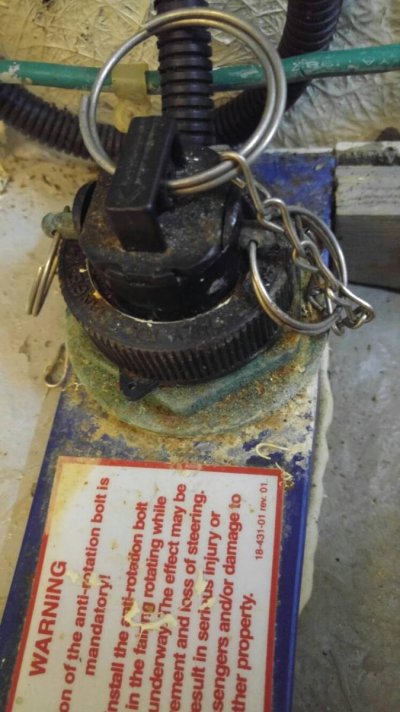

It's not cheap, but it WORKS. Use as directed, it will assist in breaking the bond. To remove the thru hull, I pulled the center paddle assembly and made a toggle with a piece of chain and a bolt. Use as big a chain as will fit into the hole, drop it through from the inside after removing the inside nut from the TXDCR. Then put some blocking against the hull, and use a 4x4 or suitable lever to lever the TXDCR out of the hull from the outside. The DeBond should be applied a half hour or hour ahead, use a razor knife to score the bead to allow the DeBond to enter the 5200 surface.

If you install the new TXDCR fairing with 5200 but use polysulfide on the TXDCR itself, when it comes time to replace, it'll pull right out and the fairing will remain intact.

Hope you can salvage the fairing, they are tedious to re-do.

As an aside, my luck with the speed paddles is perfect-100% they NEVER work for more than a few days.