You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solar Installation Guide

- Thread starter Bob Cofer

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Bob: A nice write up. It would be a great addition to the Trawler Forum Library Systems Section.

Bob and Jill:

Thanks for posting that presentation. How about posting it to the library section of this forum, so it won't get lost. Click on the icon in the upper right of this screen, pick the section and follow the directions.

Let me offer some clarification and comment, all in the spirit of positive feedback:

1. Often we don't know or even care whether a panel is mono or poly, just if it fits in the available space and gives the output we want.

2. Perhaps you could give more specifics about matching panel and controller specs, like making sure that your controller can deal with the Voc of the panel. I also have noticed that on-line panel vendors no longer advise upspecing the controller by 25% over panel wattage div 12. Have controllers gotten better, vendors less honest or what has changed.

3. For the life of me I can't see why you need overcurrent protection on the panel side of the controller. The wire should be sized to take the Isc current so what can go wrong?

4. I liked your explanation of series, paralles and series/parallel wiring.

5. I also liked your statement that for panels less than 200 watts, MPPT controllers were overkill and PWM controllers would uually do just fine. I just did a mental spec of a 300 watt system with either two 150 watt 12V nominal panels or one 300 watt 24V nominal panel. The single panel system obviously needed a MPPT controller to charge 12V batteries, but the controller cost more than the panel.

But today 24V nominal voltage panels have really gotten cheap. I just saw one for $.77 per watt, but since these big panels cannot be shipped UPS, motor freight charges can kill you if you are just buying one.

David

Thanks for posting that presentation. How about posting it to the library section of this forum, so it won't get lost. Click on the icon in the upper right of this screen, pick the section and follow the directions.

Let me offer some clarification and comment, all in the spirit of positive feedback:

1. Often we don't know or even care whether a panel is mono or poly, just if it fits in the available space and gives the output we want.

2. Perhaps you could give more specifics about matching panel and controller specs, like making sure that your controller can deal with the Voc of the panel. I also have noticed that on-line panel vendors no longer advise upspecing the controller by 25% over panel wattage div 12. Have controllers gotten better, vendors less honest or what has changed.

3. For the life of me I can't see why you need overcurrent protection on the panel side of the controller. The wire should be sized to take the Isc current so what can go wrong?

4. I liked your explanation of series, paralles and series/parallel wiring.

5. I also liked your statement that for panels less than 200 watts, MPPT controllers were overkill and PWM controllers would uually do just fine. I just did a mental spec of a 300 watt system with either two 150 watt 12V nominal panels or one 300 watt 24V nominal panel. The single panel system obviously needed a MPPT controller to charge 12V batteries, but the controller cost more than the panel.

But today 24V nominal voltage panels have really gotten cheap. I just saw one for $.77 per watt, but since these big panels cannot be shipped UPS, motor freight charges can kill you if you are just buying one.

David

The top-tier vendors are usually very clear which specs you can "push" and which are hard limits. I find most of the time the total voltage on MPPT units is strict, especially if you're tilting and might get cold clear days in winter.on-line panel vendors no longer advise upspecing the controller by 25% over panel wattage div 12. Have controllers gotten better, vendors less honest or what has changed.

Total amps is usually safe to exceed by a bit, increasing your average daily output but "wasting" some output in peak conditions.

For example, the two Bogart SC-2030s controlled by my Trimetric will accept up to 45A maximum each to avoid damage to the controller, but will never output more than 31A each.

Larry,

You can add it if you like.

Done. Thanks again.

2geer

Veteran Member

- Joined

- Feb 11, 2017

- Messages

- 29

- Location

- United States

- Vessel Name

- Stout

- Vessel Make

- Kadey Krogen 42-087

We just completed a solar install using Victron Energy's MPPT charge controller technology. We used (2) SunPower X21-345 panels in series mounted on the pilothouse roof. With the help of Victron's calculator we were able to safely match the charge controller for the installation. The calculator is at:

https://www.victronenergy.com/blog/...ar-modules-to-the-new-mppt-charge-regulators/

The above file allows you to enter the specific parameters of the panel(s) you plan to use.

Because of our existing investment in our (2) Victron's Multiplus units and Color GX display it made sense to go in this direction. With a recent test on anchor, we are very pleased with the results - no generator needed...

See attached pic...

Dave & Lisa Geer

M/V Stout KK42-087

https://www.victronenergy.com/blog/...ar-modules-to-the-new-mppt-charge-regulators/

The above file allows you to enter the specific parameters of the panel(s) you plan to use.

Because of our existing investment in our (2) Victron's Multiplus units and Color GX display it made sense to go in this direction. With a recent test on anchor, we are very pleased with the results - no generator needed...

See attached pic...

Dave & Lisa Geer

M/V Stout KK42-087

Attachments

Donsan

Guru

- Joined

- Jul 6, 2014

- Messages

- 2,300

- Location

- United States

- Vessel Name

- No Mo Trawla

- Vessel Make

- Hurricane SS188

We just completed a solar install using Victron Energy's MPPT charge controller technology. We used (2) SunPower X21-345 panels in series mounted on the pilothouse roof. With the help of Victron's calculator we were able to safely match the charge controller for the installation. The calculator is at:

https://www.victronenergy.com/blog/...ar-modules-to-the-new-mppt-charge-regulators/

The above file allows you to enter the specific parameters of the panel(s) you plan to use.

Because of our existing investment in our (2) Victron's Multiplus units and Color GX display it made sense to go in this direction. With a recent test on anchor, we are very pleased with the results - no generator needed...

See attached pic...

Are there any issues on the fly bridge of glare or heat from the panels in your setup?

2geer

Veteran Member

- Joined

- Feb 11, 2017

- Messages

- 29

- Location

- United States

- Vessel Name

- Stout

- Vessel Make

- Kadey Krogen 42-087

We have had them operational less than a month. No problems with glare or heat as of yet. Spent the day the pic was taken operating from the flybridge with no issue.

The view is taken looking south into Willsboro Bay on Lake Champlain approximately here:

https://www.google.com/maps/dir/44.448087,-73.3891208//@44.4233346,-73.4079684,14z

Dave Geer

The view is taken looking south into Willsboro Bay on Lake Champlain approximately here:

https://www.google.com/maps/dir/44.448087,-73.3891208//@44.4233346,-73.4079684,14z

Dave Geer

This is a presentation that I gave at the PSGBOA Rendezvous. It is basic but gives an idea of the process.

On Ebbtide 600w gives us a nice surplus and we can now make ice via the inverter while on the hook!

Safe travels,

Bob & Jill

Great presentation ! thanks for sharing.

I'm surprised that no mention was made of RFI generated by some ( obscure or off shore made ) MPPT controllers. I have seen it first hand where it will CHOKE all your VHF / FM / TV etc. In the end, you get what you pay for. fb

foggysail

Guru

I read Bob Cofer's Solar Presentation pdf and found it informative although I do have an exception. That exception pertains to shading and how it affects an entire string. This topic got me into a discussion with John61ct in another forum.

There is a belief out there that alludes one to believe that series strings should be avoided because of the calamitous impact that results from shading. I say that the problems caused by shading are small compared to operating lower Vpp panels in parallel. Parallel operation imposes demands for heavier wiring from the the panels to the controller. If one skimps on the wire installation between the panels and the controller.....for this discussion I am focusing only on an MPPT....... there will be times of maximum sun that results in the controller operating off the Vpp resulting in lost power transfer. This can last for hours!

OK, now consider shading. Bob's pdf claims that shading of one cell kills the entire string of series panels. That was true before bypass diodes were introduced and most panels today have them. Panel bypass diodes allows current to flow as if that shaded panel was absent. Yes, there will be a performance hit although the hit will be less as the number of panels in series increases. There will still be a loss though.

But we are focusing on shading and most shading is not constant so the shading impact will only last for the length of time the panel is shaded. Not so with compromised wiring. OK, sure! Just increase the wire sizes and avoid the problem. Well, there again the shade problem is still there so you can still lose a panel. Also how many of you have pulled #6 or worse #4 wires from panels to a controller? On my boat I would need to enlarge.... no! make that drill new holes in the fiberglass for the heavy wires to pass through. Big PITA!

So although I acknowledge that shading is a problem, over all it is something that I can live with because the shade is not permanent...momentary in most cases.

I am in the process of upgrading my solar. I have so far installed a new Victron 150-70 controller (downgraded my earlier plan for 150-85) and am in the process of purchasing 4 new Canadian CS6K295MS panels. My intention is to wire them in either series/parallel or just series. I am leaning toward just going series so my Vpp will be in the 120-130 volt range, well within the new controllers 150 volt limit. And by the way, when operating at these higher voltages it behooves all to consider adding a panel disconnect switch. I recommend switches anyway even with lower voltages. Think what can happen to a finger or a wrist if ring or a wrist watch shorts out a panel's current especially if the current is high.

Anyway, just wanted to share my technical thoughts on this topic and I know many will still believe shading is a death knell to series strings.

There is a belief out there that alludes one to believe that series strings should be avoided because of the calamitous impact that results from shading. I say that the problems caused by shading are small compared to operating lower Vpp panels in parallel. Parallel operation imposes demands for heavier wiring from the the panels to the controller. If one skimps on the wire installation between the panels and the controller.....for this discussion I am focusing only on an MPPT....... there will be times of maximum sun that results in the controller operating off the Vpp resulting in lost power transfer. This can last for hours!

OK, now consider shading. Bob's pdf claims that shading of one cell kills the entire string of series panels. That was true before bypass diodes were introduced and most panels today have them. Panel bypass diodes allows current to flow as if that shaded panel was absent. Yes, there will be a performance hit although the hit will be less as the number of panels in series increases. There will still be a loss though.

But we are focusing on shading and most shading is not constant so the shading impact will only last for the length of time the panel is shaded. Not so with compromised wiring. OK, sure! Just increase the wire sizes and avoid the problem. Well, there again the shade problem is still there so you can still lose a panel. Also how many of you have pulled #6 or worse #4 wires from panels to a controller? On my boat I would need to enlarge.... no! make that drill new holes in the fiberglass for the heavy wires to pass through. Big PITA!

So although I acknowledge that shading is a problem, over all it is something that I can live with because the shade is not permanent...momentary in most cases.

I am in the process of upgrading my solar. I have so far installed a new Victron 150-70 controller (downgraded my earlier plan for 150-85) and am in the process of purchasing 4 new Canadian CS6K295MS panels. My intention is to wire them in either series/parallel or just series. I am leaning toward just going series so my Vpp will be in the 120-130 volt range, well within the new controllers 150 volt limit. And by the way, when operating at these higher voltages it behooves all to consider adding a panel disconnect switch. I recommend switches anyway even with lower voltages. Think what can happen to a finger or a wrist if ring or a wrist watch shorts out a panel's current especially if the current is high.

Anyway, just wanted to share my technical thoughts on this topic and I know many will still believe shading is a death knell to series strings.

Last edited:

psneeld

Guru

For newbies....yes a lot of good tech advice...

A lot of which is frogs hair.

I bought 4 100W panels, put them in parralel with adequate wiring and the give away PWM controller.

Works great, wired per diagrams, hinged install on 2 panels allows for maximum output, 2 moveable panels allows for even more flexibility.

Sure ..... read all the literature and expert advice....go that way if desired, but my system has all but eliminated my daily genset runs and does the trick without higher tier engineering.

No need for an engineering degree and worry about frogs hair, you can buy 400W of panels and be up and running in a day. Renology from Amazon for less than $600..

Not saying there isnt perfection in a solar system...just dont be afraid to jump in, as it is really pretty simple if you let it be.

A lot of which is frogs hair.

I bought 4 100W panels, put them in parralel with adequate wiring and the give away PWM controller.

Works great, wired per diagrams, hinged install on 2 panels allows for maximum output, 2 moveable panels allows for even more flexibility.

Sure ..... read all the literature and expert advice....go that way if desired, but my system has all but eliminated my daily genset runs and does the trick without higher tier engineering.

No need for an engineering degree and worry about frogs hair, you can buy 400W of panels and be up and running in a day. Renology from Amazon for less than $600..

Not saying there isnt perfection in a solar system...just dont be afraid to jump in, as it is really pretty simple if you let it be.

I was never arguing S vs P.

I'm saying putting the panels on a greater number of smaller controllers

ideally, a 75/15 on each, or

next best, a 100/30 per pair

would give you significantly higher total power output per day in real life due to sail/rigging shadows passing over the panels

The extra expense is minimal if any

Yes the wiring a bit more trouble.

Up to you if the difference is worth it, but please don't try to deny there is a difference.

In the old days you just couldn't get four excellent full-featured MPPT controllers for ~$400 delivered.

But now you can.

I'm saying putting the panels on a greater number of smaller controllers

ideally, a 75/15 on each, or

next best, a 100/30 per pair

would give you significantly higher total power output per day in real life due to sail/rigging shadows passing over the panels

The extra expense is minimal if any

Yes the wiring a bit more trouble.

Up to you if the difference is worth it, but please don't try to deny there is a difference.

In the old days you just couldn't get four excellent full-featured MPPT controllers for ~$400 delivered.

But now you can.

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

I appreciate reading these discussions because I learn a bit more each time. The presentation by Bob was very helpful.

Eventually, I want to do what Rebel did and put two panels on my PH roof (that is Pilothouse not Principle Home). Reading the information on solar is very helpful.

Eventually, I want to do what Rebel did and put two panels on my PH roof (that is Pilothouse not Principle Home). Reading the information on solar is very helpful.

twistedtree

Guru

There has been a really good discussion on Cruisers Forum on serial vs parallel, including an excellent model run by a very competent electrical engineer. There are infinite shading scenarios to consider, and different panel cell layouts, so there are no absolutes. But assuming modern panels with bypass and blocking diodes, and assuming a good MPPT charge controller, series wiring almost always wins. Not always, but you have much better chances. How you physically arrange your panels matters too.

Per-panel charge controllers is probably the ultimate, if the costs etc work for you.

Per-panel charge controllers is probably the ultimate, if the costs etc work for you.

Pgitug

Guru

I just took two solar panels off my new to me tug. The controller had failed and cooked the house batteries with high voltage. Also the previous owner had no means to wash the boat section under the panels so The fiberglass now has black mold growth that has stained the gel coat. I am not a fan of what it takes to operate solar on a trawler.

Donsan

Guru

- Joined

- Jul 6, 2014

- Messages

- 2,300

- Location

- United States

- Vessel Name

- No Mo Trawla

- Vessel Make

- Hurricane SS188

Poor installs making maintenance difficult or an issue is bad for any system, not just solar.

Seems to be way more satisfied than dissatisfied solar users.

Do you have suggestions on how to clean under the panels?

psneeld

Guru

Do you have suggestions on how to clean under the panels?

If it was my install and they weren't high enough to get under, they would be hinged on one side and pinned on the other.

Even better, they would be pinned on both sides for easy removal and have leg supports to possibly be tilted for better sun angle.

Donsan

Guru

- Joined

- Jul 6, 2014

- Messages

- 2,300

- Location

- United States

- Vessel Name

- No Mo Trawla

- Vessel Make

- Hurricane SS188

If it was my install and they weren't high enough to get under, they would be hinged on one side and pinned on the other.

Even better, they would be pinned on both sides for easy removal and have leg supports to possibly be tilted for better sun angle.

Haven't seen a lot of installs but almost all have been with very little space under the panels.

Your suggestion sounds good but it seems like most of the mount designers are completely clueless. Have you seen mounts like that from a vendor? IMHO, the mounts have always been the weakest like in solar on boats.

psneeld

Guru

Usually vender stuff is at best, half way to a good design.

Not always, but on boats, often.

Plus, most solar is for land based stuff so I wouldn't have even bothered because of additional adaptation or materials.

Not always, but on boats, often.

Plus, most solar is for land based stuff so I wouldn't have even bothered because of additional adaptation or materials.

Sunset

Senior Member

- Joined

- May 12, 2013

- Messages

- 278

- Location

- Canada

- Vessel Name

- Manatee

- Vessel Make

- 1976 Albin 25 DeLuxe

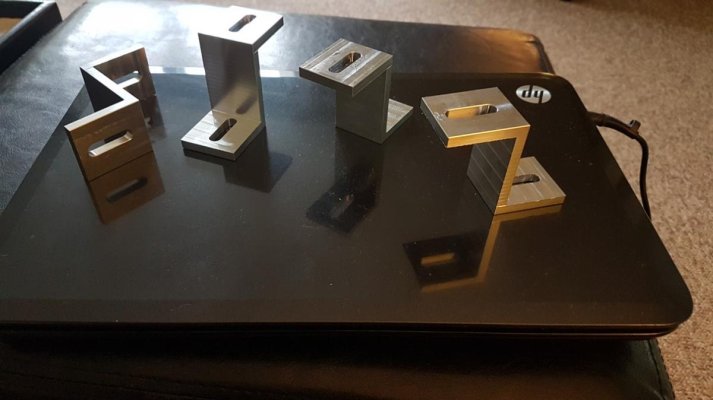

I'll take one this weekend. They cost me $90 to have the guy design and make them. Which is a lot of money for a few brackets, but not so much when you think of the process and the custom design. And I got to visit their totally cool facility, where upstairs they are working on space sat stuff. The fabrication work is a side hustle because they have these hi-tech cad-cam computers and other big techy machines of which I know naught. When I saw what they do I wanted to go back in time and have a career doing that kind of thing!

JustBob

Senior Member

- Joined

- Apr 12, 2016

- Messages

- 496

- Location

- USA

- Vessel Name

- Mahalo

- Vessel Make

- 2018 Hampton Endurance 658

Electricity is my weak point when it comes to boat systems. So I'll throw this one out there to you guys. Just looking for a rough or SWAG figure.

Say I had room on the flybridge hardtop for ~100 sq feet of solar panels. And the panels/chargers are today's state of the art units.

Say it's a mostly sunny day in the summer time.

Without getting into nuances like latitude and other details, how long do I have to run my 20kw generator to equal the amount of electricity generated by my hypothetical panels?

Say I had room on the flybridge hardtop for ~100 sq feet of solar panels. And the panels/chargers are today's state of the art units.

Say it's a mostly sunny day in the summer time.

Without getting into nuances like latitude and other details, how long do I have to run my 20kw generator to equal the amount of electricity generated by my hypothetical panels?

twistedtree

Guru

This is a serious SWAG, but let's say yo can fit 1kw of panels, and get 5hrs of full sun equivalent output. That's 5kwh per day. That's 15 minutes of gen run time at full output.

Now if you are wondering how much gen run time the panels will save, it's actually better than that because your chargers are very unlikely to consume the full 20kw of your gen. You might have 3-6kw of charger capacity, so you are looking at more like a full hour of run time.

Now if you are wondering how much gen run time the panels will save, it's actually better than that because your chargers are very unlikely to consume the full 20kw of your gen. You might have 3-6kw of charger capacity, so you are looking at more like a full hour of run time.

If the use case is charging batteries on the hook long-term, with that much genny all solar will do for you ishow long do I have to run my 20kw generator to equal the amount of electricity generated by my hypothetical panels?

greatly reduce genny runtime

triple the life of your bank, making it worthwhile spending more on quality

If you're already burning dino juice 5+ hours most days, then probably solar is not worth it.

psneeld

Guru

I find with solar, keeping the batts up all day, you dont need to run the genny till you lose too much energy from the batts.

Lets the batts get low, and it takes hours for the genset to charge them up...but kerp the charge up all day long, it takes little or no charging from the genset.

Lets the batts get low, and it takes hours for the genset to charge them up...but kerp the charge up all day long, it takes little or no charging from the genset.

foggysail

Guru

This is a serious SWAG, but let's say yo can fit 1kw of panels, and get 5hrs of full sun equivalent output. That's 5kwh per day. That's 15 minutes of gen run time at full output.

Now if you are wondering how much gen run time the panels will save, it's actually better than that because your chargers are very unlikely to consume the full 20kw of your gen. You might have 3-6kw of charger capacity, so you are looking at more like a full hour of run time.

Twisted's numbers look OK without running the math. There are things though that are simplified. For example, assume only a 3KW charger charging a 12 V bank. The battery bank would need to accept is 3000/12 or more realistically 3000/14 = 214 amps. Of course, there are losses to contend with which I have neglected.

This is a very large charger and you will need a huge battery bank to accept the charge. Your generator is not as good as one would like for charging batteries. You will have to run your genny for hours depending again on the charger along with how large the bank is.

Now consider solar and Twisted's assumptions...1KW in panels and an MPPT controller (high nineties for efficiency) charging currents will be about 1000/14= 71 amps for 5 hours or 355 amp hours returned to your battery bank. And when the batteries are fully charged the controller will enter float mode with very little current being supplied to the bank. IMHO-- SOLAR is the way to go and on top of that, it is silent!

Similar threads

- Replies

- 7

- Views

- 621

- Replies

- 281

- Views

- 30K