You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Should I leave air space in my dry stacks?

- Thread starter swampu

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Xsbank

Guru

- Joined

- Sep 7, 2013

- Messages

- 3,791

- Location

- Canada

- Vessel Name

- Gwaii Haanas

- Vessel Make

- Custom Aluminum 52

My stack is tightly insulated but the area around it is open, it is also the main vent for my engine room as my "funnel" has vents too. I have large air intakes in the side of the engine room so it clears the heat out a lot faster. My space where the stack goes is also lined with sheet metal.

Sooner or later you will need to service or replace the muffler and resonator (if there is one - my boat didn't have one when I bought it) so I would spend some effort making access panels to get in there. Also, don't forget expansion - you need joints and supports that will allow this. Don't forget that when you are running there is a LOT of heat.

Sooner or later you will need to service or replace the muffler and resonator (if there is one - my boat didn't have one when I bought it) so I would spend some effort making access panels to get in there. Also, don't forget expansion - you need joints and supports that will allow this. Don't forget that when you are running there is a LOT of heat.

Ski in NC

Technical Guru

The air space in the stack chase needs to be vented at bottom and at top. The insulation around the pipe reduces heat transfer, but does not eliminate it. Some heat makes it though the insulation and will heat up the air in the void space. That heat needs a path for convection to carry it out. If the chase was sealed up, temps inside will gradually rise to dangerous levels.

The Other Gary

Senior Member

- Joined

- Sep 18, 2016

- Messages

- 336

- Location

- Canada

- Vessel Name

- Adios Dinero

- Vessel Make

- Bayliner 3988 2 x 330 Cummins

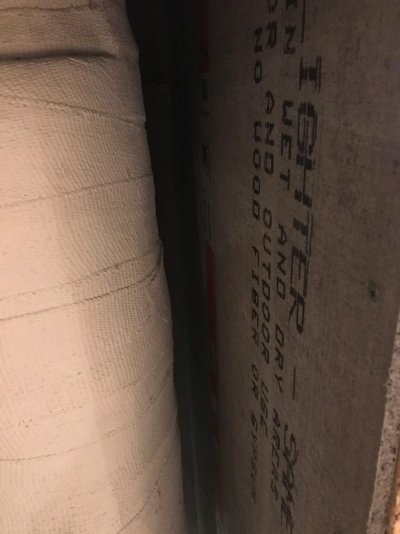

That is a scary looking installation, especially with paper backed fiberglass insulation.

I suggest that you remove it, screw sheet metal to the inside of your framing, add a louvered vent to the exterior wall at the top and bottom of the pipe compartment to vent heat. You can then insulate between the studs with 2 inch foam siding board on the outside of the metal. You may want to modify your framing to make a removable panel as well for future maintenance access.

I suggest that you remove it, screw sheet metal to the inside of your framing, add a louvered vent to the exterior wall at the top and bottom of the pipe compartment to vent heat. You can then insulate between the studs with 2 inch foam siding board on the outside of the metal. You may want to modify your framing to make a removable panel as well for future maintenance access.

psneeld

Guru

From my professional marine engineer friend....

"... that boat has already had one fire, it looks like he is setting it up for another!

All that dry wood so close to the stack, "insulated" or not, presents a serious fire hazard. That guy needs to go look at some dry stack workboat exhaust systems."

"... that boat has already had one fire, it looks like he is setting it up for another!

All that dry wood so close to the stack, "insulated" or not, presents a serious fire hazard. That guy needs to go look at some dry stack workboat exhaust systems."

RT Firefly

Enigma

Greetings,

I wonder if something like this would work. Maybe in a 4" size or so...

DuraTech 5-inch Chimney

I wonder if something like this would work. Maybe in a 4" size or so...

DuraTech 5-inch Chimney

Roamer Blue

Senior Member

Greetings,

I wonder if something like this would work. Maybe in a 4" size or so...

DuraTech 5-inch Chimney

1000 degree F continuous going to be ok for the engine involved?

RB

Keysdisease

Guru

That is a scary looking installation, especially with paper backed fiberglass insulation.

I suggest that you remove it, screw sheet metal to the inside of your framing, add a louvered vent to the exterior wall at the top and bottom of the pipe compartment to vent heat. You can then insulate between the studs with 2 inch foam siding board on the outside of the metal. You may want to modify your framing to make a removable panel as well for future maintenance access.

What he said

RT Firefly

Enigma

Greetings,

Mr. RB. VERY valid point. I would defer to Mr. ps's "professional marine engineer" friend. Thank you.

Mr. RB. VERY valid point. I would defer to Mr. ps's "professional marine engineer" friend. Thank you.

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,196

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Examples and detailed designs for properly constructed dry stack setups are not difficult to find. Swampu, have you looked at ABYC guidelines for their recommendations?

A trip onboard a dry stack Nordhavn would be instructive. Psneelds friend would be a great contact for getting advice and benchmark designs as well as recommended materials of construction.

Good luck.

A trip onboard a dry stack Nordhavn would be instructive. Psneelds friend would be a great contact for getting advice and benchmark designs as well as recommended materials of construction.

Good luck.

Maerin

Guru

I'd treat that chase like a chimney, e.g. would it withstand open flame? There is available a variety of silicate type board that is virtually fireproof. Even so, I think it'd be prudent to have a sheet metal backing of a minimum of 26ga. galvanized steel (not aluminum). Presume that the exhaust pipe will come apart, and have the chase designed to withstand that sort of scenario.

As ski correctly pointed out, the insulation slows down the rate of transfer, it does not stop it or eliminate it. Provide a means to remove the heat, and create a fireproof chase in the event something goes wrong.

There's a safe way to accomplish what you need, I don't think the picture is it!

As ski correctly pointed out, the insulation slows down the rate of transfer, it does not stop it or eliminate it. Provide a means to remove the heat, and create a fireproof chase in the event something goes wrong.

There's a safe way to accomplish what you need, I don't think the picture is it!

Spottsville

Senior Member

- Joined

- May 3, 2012

- Messages

- 265

- Location

- US

- Vessel Name

- Quiet Company

- Vessel Make

- Great Harbour GH-47

A commercial industrial insulator is a professional trade and should be consulted! Looks like trouble......

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Extra space in the stack chase can be useful as a wet locker .

Similar threads

- Replies

- 7

- Views

- 912