Nomad Willy

Guru

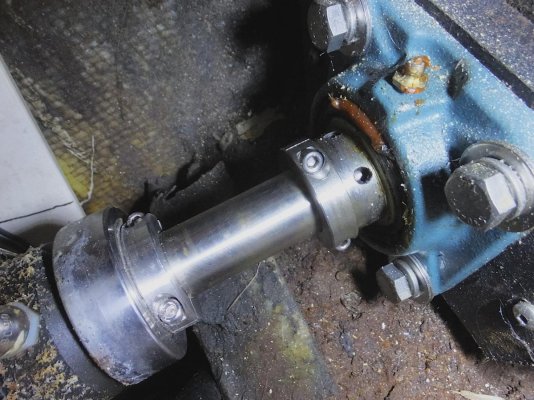

I asked for a new intermediate bering to be installed. The yard tried to remove the old bearing by cutting it out. But they cut into the shaft. They then finished the job of cutting it out. They made me a new shaft and finished the installation. But the guys put a locking collar on the shaft just behind the inner race of the ball bearing thus turning it into a thrust bearing.

It's my understanding that the propeller shaft needs to move back and forth as the power pulses push like a jackhammer every time a cylinder fires. Also from my understanding engine mounts allow for fore and aft movement as part of their design.

In the first pic the collar is tight on the shaft as the yard birds installed it. The second pic is where I have it now .. against the PSS bearing. In the past I've had problems w the PSS bearing moving fwd far enough to allow a great deal of water to enter the boat. Since the collar was there I put it to work.

IMO the yard should have omitted the locking collar against the int. brng entirely. The presence of the collar against the inner race of the brng turns the brng into a thrust brng and does not allow the shaft to move fwd and aft. This in turn transfers the fore and aft vibration from the shaft into the boat hull through the int shaft brng mounting.

After a run lasting hours I discovered the int. brng was quite hot. Hot enough so I was only able to touch it for 1 second. I pumped a little more grease into the brng. Did little if any good. I noticed after a test run later at the dock that the collar had been slipping on the fore and aft face of both the int. brng and the collar .. taking the thrust of the shaft. So probably the collar was acting like a dry steel to steel thrust brng Bad.

That's when I moved the collar aft against the PSS. Haven't been out w the boat since that move. I hope that now the shaft will move freely fore and aft and allow the fore and aft movement to be transferred to the engine mounts where it belongs IMO. And that the whole arrangement runs nice and cool.

My question is have I misunderstood the way the intermediate shaft bearing is designed to work or what? If the shaft slides freely on the inner race of the int shaft brng the big ball brng becomes a plain brng. The ball brng is low drag so w a loose fitting shaft to inner race there would be either a lot of wear on the shaft or the vibration is sent to the boat hull via the brng mount.

How is this supposed to work?

It's my understanding that the propeller shaft needs to move back and forth as the power pulses push like a jackhammer every time a cylinder fires. Also from my understanding engine mounts allow for fore and aft movement as part of their design.

In the first pic the collar is tight on the shaft as the yard birds installed it. The second pic is where I have it now .. against the PSS bearing. In the past I've had problems w the PSS bearing moving fwd far enough to allow a great deal of water to enter the boat. Since the collar was there I put it to work.

IMO the yard should have omitted the locking collar against the int. brng entirely. The presence of the collar against the inner race of the brng turns the brng into a thrust brng and does not allow the shaft to move fwd and aft. This in turn transfers the fore and aft vibration from the shaft into the boat hull through the int shaft brng mounting.

After a run lasting hours I discovered the int. brng was quite hot. Hot enough so I was only able to touch it for 1 second. I pumped a little more grease into the brng. Did little if any good. I noticed after a test run later at the dock that the collar had been slipping on the fore and aft face of both the int. brng and the collar .. taking the thrust of the shaft. So probably the collar was acting like a dry steel to steel thrust brng Bad.

That's when I moved the collar aft against the PSS. Haven't been out w the boat since that move. I hope that now the shaft will move freely fore and aft and allow the fore and aft movement to be transferred to the engine mounts where it belongs IMO. And that the whole arrangement runs nice and cool.

My question is have I misunderstood the way the intermediate shaft bearing is designed to work or what? If the shaft slides freely on the inner race of the int shaft brng the big ball brng becomes a plain brng. The ball brng is low drag so w a loose fitting shaft to inner race there would be either a lot of wear on the shaft or the vibration is sent to the boat hull via the brng mount.

How is this supposed to work?

Attachments

Last edited: