Portuguese

Guru

Guys

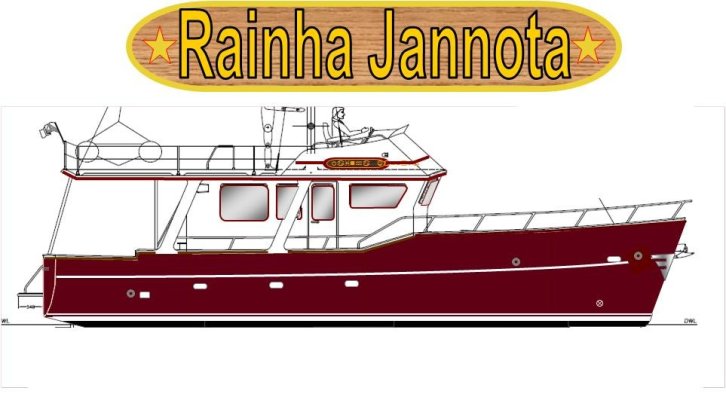

This is my boat soon...very soon! It will be called Rainha Jannota (Queen Jannota) In honor of my wife and admiral, Ms Jana

LOA 46', LWL 40.12', Disp 55000 lbs, single Deutz T*145 HP @ 2500 RPM qith 33.5" x 26" 4 blade propeller

*

This is my boat soon...very soon! It will be called Rainha Jannota (Queen Jannota) In honor of my wife and admiral, Ms Jana

LOA 46', LWL 40.12', Disp 55000 lbs, single Deutz T*145 HP @ 2500 RPM qith 33.5" x 26" 4 blade propeller

*

Attachments

-

render.jpg91.3 KB · Views: 125

render.jpg91.3 KB · Views: 125 -

f1_chegandomadeira.jpg178.1 KB · Views: 92

f1_chegandomadeira.jpg178.1 KB · Views: 92 -

f14_cavpicadeiro 2.jpg153 KB · Views: 90

f14_cavpicadeiro 2.jpg153 KB · Views: 90 -

f19_destaque_roda%20de%20proa.jpg98.6 KB · Views: 81

f19_destaque_roda%20de%20proa.jpg98.6 KB · Views: 81 -

f30_tunel_bt.jpg204 KB · Views: 100

f30_tunel_bt.jpg204 KB · Views: 100 -

f37_destaque_proa.jpg127.1 KB · Views: 84

f37_destaque_proa.jpg127.1 KB · Views: 84 -

f42_coberto.jpg65.5 KB · Views: 86

f42_coberto.jpg65.5 KB · Views: 86 -

f46_bolinalateral.jpg66 KB · Views: 83

f46_bolinalateral.jpg66 KB · Views: 83 -

f53_laminacao_1.jpg64.8 KB · Views: 88

f53_laminacao_1.jpg64.8 KB · Views: 88 -

f54_laminacao_1.jpg50 KB · Views: 77

f54_laminacao_1.jpg50 KB · Views: 77