ABfish

Senior Member

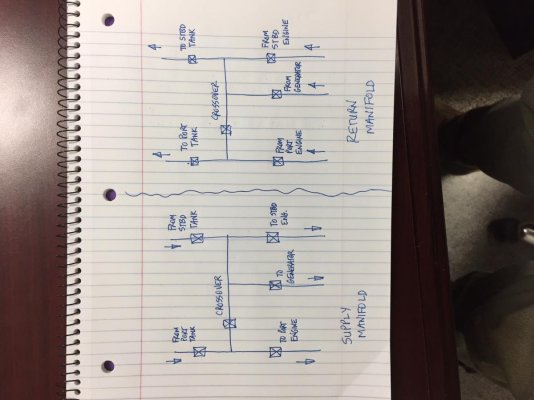

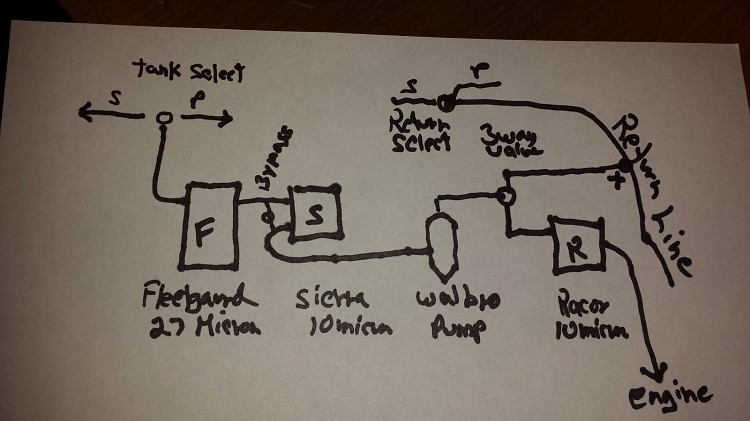

My boat has twin engines, twin fuel tanks of 300 gallons each. It has two fuel manifolds, one for the fuel delivery, and one for the return to the tanks.

I ran both engines out of fuel this weekend. While running at cruising speed, one engine died, then the other. One tank was empty, the other tank contained more than 200 gallons.

The fuel crossover valves, both supply and return, were open so that both engines could draw from either tank and return to either tank.

My question: How did I suck one tank completely dry?

The valves have not been operated since I've owned the boat, and I've run at least 600 gallons though the engines in the past year.

I ran both engines out of fuel this weekend. While running at cruising speed, one engine died, then the other. One tank was empty, the other tank contained more than 200 gallons.

The fuel crossover valves, both supply and return, were open so that both engines could draw from either tank and return to either tank.

My question: How did I suck one tank completely dry?

The valves have not been operated since I've owned the boat, and I've run at least 600 gallons though the engines in the past year.