Capt. Jon

Guru

Last December we had a major overhaul on the port engine. This was due to a leaking after cooler issue which hydraulically locked the engine on startup. The engine is a 3208TA 375 and currently has 250+ hours since the major with 1650 hours total time.

Since I did not get the opportunity to use the boat much over the winter I only put less than 20 hours on the engine until our summer trip at the end of May. Just before the trip I changed the oil in that engine (Caterpillar and the mechanic recommended 50 hours) and after speaking to the mechanic who did the work and to Caterpillar I decided not to do an oil sample due to the low time on that oil. Just did not want to change it during the trip.

Our trip up the Tenn-Tom lasted 15 days and resulted in close to 80 hours engine time plus the additional hours we ran the boat while in Tennessee for the summer. By the time we were ready to make the return trip the engine hours had on that oil had exceeded 150 hours so I decided it was time to change it and sample it. I also at that point checked the coolant tank and estimated it to be about 1/2 gallon low on coolant. This was added before the return trip.

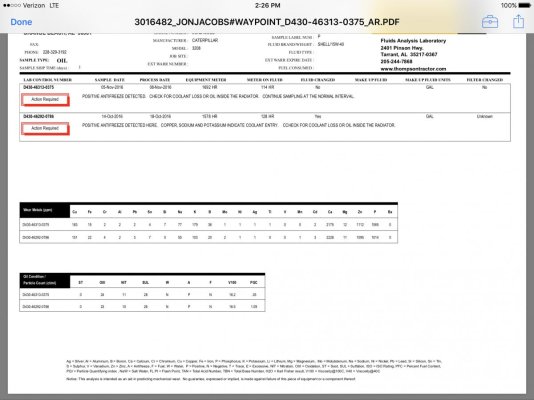

While on the return trip I received the results back via email for that engine indicating that there was coolant intrusion into the oil. This was indicated by the fact that excessive copper, sodium and potassium was present in that sample. When I inspected the engine during a routine morning check the next day before departing the coolant level was fine with no loss.

This same day we were held up by a lock for 3.5 hours. So, in order to make up some time to the next anchorage I pushed the boat up from my normal 1400 rpm cruising speed to 2200 rpm for about 2 hours. Again the following morning during routine engine checks before departure the coolant level was again 1/2 gallon low. I will also add during the previous days's running the engine has never run hot nor has steam been observed from the exhaust plume.

Durning the days remaining on this trip until we returned the boat was run at 1400 rpm until the last day in when which I ran the boat about 30 minutes at 2200 rpm before entering the marina.

I've checked the coolant since arriving and there is no indication that it has lost anymore coolant since the hard 2 hour run several days earlier when coolant was added and the additional 30 minute run before entering the marina.

So I guess I am looking for suggestions on where to start looking for coolant leaks. I did pull the oil drain plug after 24 hours of sitting to see if there was any indication of coolant in the bottom of the oil pan. There was none. I also retested the oil with a second sample just in case there may have been some type of lab mistake. Today I received the results and the sample again tested positive for the contamination.

Since I did not get the opportunity to use the boat much over the winter I only put less than 20 hours on the engine until our summer trip at the end of May. Just before the trip I changed the oil in that engine (Caterpillar and the mechanic recommended 50 hours) and after speaking to the mechanic who did the work and to Caterpillar I decided not to do an oil sample due to the low time on that oil. Just did not want to change it during the trip.

Our trip up the Tenn-Tom lasted 15 days and resulted in close to 80 hours engine time plus the additional hours we ran the boat while in Tennessee for the summer. By the time we were ready to make the return trip the engine hours had on that oil had exceeded 150 hours so I decided it was time to change it and sample it. I also at that point checked the coolant tank and estimated it to be about 1/2 gallon low on coolant. This was added before the return trip.

While on the return trip I received the results back via email for that engine indicating that there was coolant intrusion into the oil. This was indicated by the fact that excessive copper, sodium and potassium was present in that sample. When I inspected the engine during a routine morning check the next day before departing the coolant level was fine with no loss.

This same day we were held up by a lock for 3.5 hours. So, in order to make up some time to the next anchorage I pushed the boat up from my normal 1400 rpm cruising speed to 2200 rpm for about 2 hours. Again the following morning during routine engine checks before departure the coolant level was again 1/2 gallon low. I will also add during the previous days's running the engine has never run hot nor has steam been observed from the exhaust plume.

Durning the days remaining on this trip until we returned the boat was run at 1400 rpm until the last day in when which I ran the boat about 30 minutes at 2200 rpm before entering the marina.

I've checked the coolant since arriving and there is no indication that it has lost anymore coolant since the hard 2 hour run several days earlier when coolant was added and the additional 30 minute run before entering the marina.

So I guess I am looking for suggestions on where to start looking for coolant leaks. I did pull the oil drain plug after 24 hours of sitting to see if there was any indication of coolant in the bottom of the oil pan. There was none. I also retested the oil with a second sample just in case there may have been some type of lab mistake. Today I received the results and the sample again tested positive for the contamination.

Last edited: