Pgitug

Guru

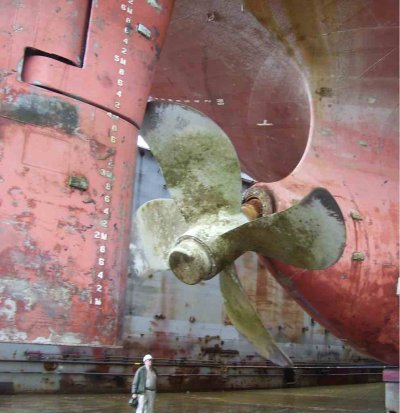

A friend of mine just lost power while running at cruise speed.

The problem turns out that his propeller shaft fractured and broke off. There was no strut. The shaft extended less than an inch out from the cutlass bearing to the propeller. Both the propeller and shaft were lost.

30 foot trawler with Cummins 220 hp.

Anyone else have this happen?

How many folks carry a spare propeller shaft?

Or a spare propeller?

I am considering getting a back up.

The problem turns out that his propeller shaft fractured and broke off. There was no strut. The shaft extended less than an inch out from the cutlass bearing to the propeller. Both the propeller and shaft were lost.

30 foot trawler with Cummins 220 hp.

Anyone else have this happen?

How many folks carry a spare propeller shaft?

Or a spare propeller?

I am considering getting a back up.