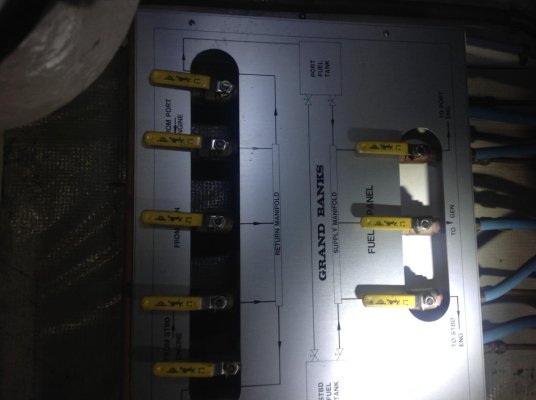

Interesting. Also neat how one is labeled "Sunction," I have not seen that before.

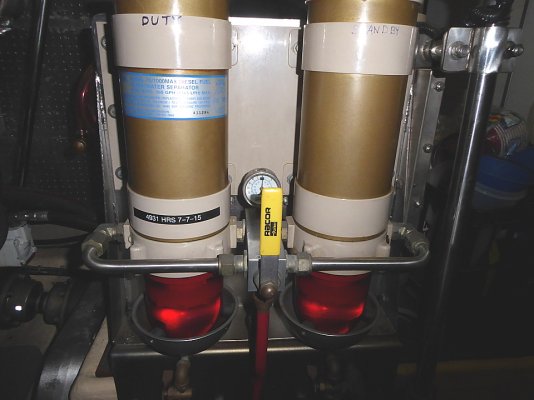

That picture of your Racor filter and filter valve does raise another question for me though.

When I got the boat the valve for the duty and standby was set to both. For now I have left it that way.

Last weekend on a trip with other boaters I raised the question. My thought being you should really run through the duty and if you have an issue there switch to the standby while your replace the duty. That way bad fuel will not take the engine down. He told me that his filters are also set to both at the advice of his mechanic.

I don't get it. I am having the Lugger guy come before the end of the year to do the annual and this is YET another question I have!

It could be that while in US waters, where fuel is more reliable, you get longer between filter changes, watch your filter pressure gauge, and then change both at the same time.

But not sure that is the best way all the same.