Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

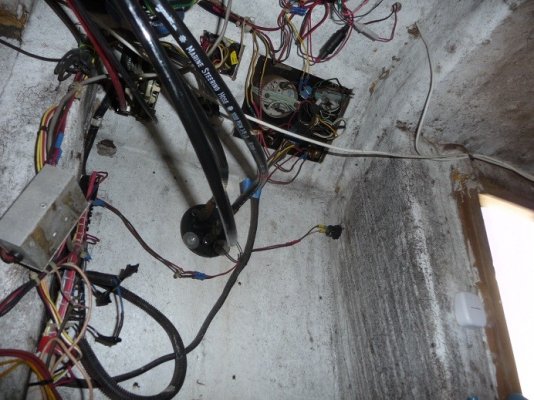

Well, now that the fuel rig is up and running (95% anyway), the next project is to upgrade and neaten the wiring under the dash. As I have said before, the PO may have been an artist with wood, but he was no electrician (unless "artist with electrical tape" counts).

I spent about an hour under there yesterday just looking, following wires, doing some labeling, and generally getting to know what is going on under there. It looks like I'll need a few terminal blocks, a lot of wire, and I was thinking of adding a positive terminal buss to add a few power options in the future.

Any help you guys and gals can be would be lovely.

It's not too bad looking and I don't expect it to be more than about $100 in parts. I'm just planning on a decent chunk of time that will need to be invested. While there is a lot of room to squirm around in there and even sit up, getting into and out of that space sucks a little. Oh well...

Here are a few pics of the job ahead.

1) Flybridge dash from the top.

2) Looking up from the underside.

3) Closeup of upper portion

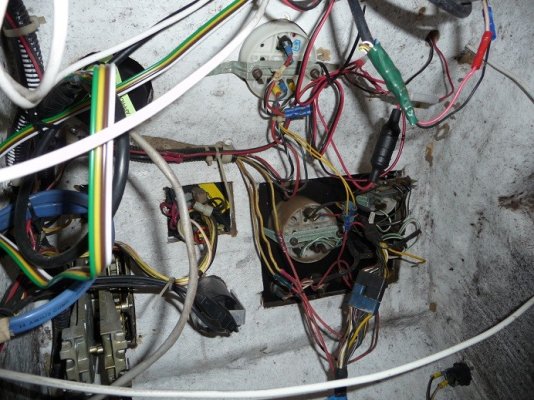

4) Closeup of primary terminal strip

5) Closeup of another messy spot under there. Horns, AM/FM antenna, high water buzzer, etc.

Tom-

I spent about an hour under there yesterday just looking, following wires, doing some labeling, and generally getting to know what is going on under there. It looks like I'll need a few terminal blocks, a lot of wire, and I was thinking of adding a positive terminal buss to add a few power options in the future.

Any help you guys and gals can be would be lovely.

It's not too bad looking and I don't expect it to be more than about $100 in parts. I'm just planning on a decent chunk of time that will need to be invested. While there is a lot of room to squirm around in there and even sit up, getting into and out of that space sucks a little. Oh well...

Here are a few pics of the job ahead.

1) Flybridge dash from the top.

2) Looking up from the underside.

3) Closeup of upper portion

4) Closeup of primary terminal strip

5) Closeup of another messy spot under there. Horns, AM/FM antenna, high water buzzer, etc.

Tom-