cappy208

Guru

These barges are typically so overbuilt that it matter not how they are (un)loaded.

The 'under 200' sized little barges in the gravel trade are made to withstand being grounded while being (un)loaded that it is not a stress issue with them.

However, the free surface inside the tanks (which ARE supposed to be free of water) is often an issue. I have seen several around New York harbor flipped in my career. The water being pumped out is an issue. Keeping it out is another issue. The front barge (Bernoullis' principle) in a tow is susceptible to being constantly head down, thus the forward tanks being full of water.

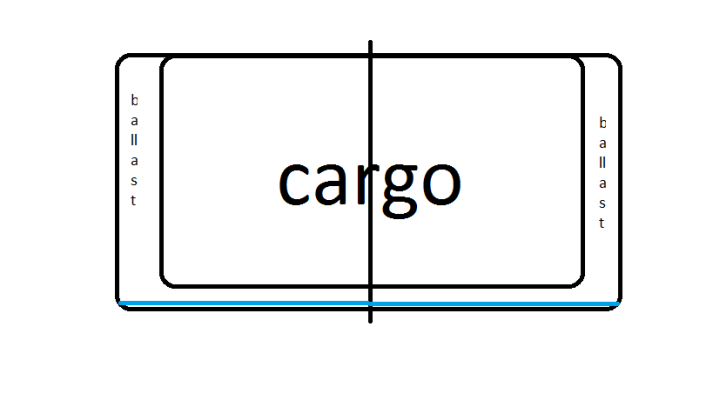

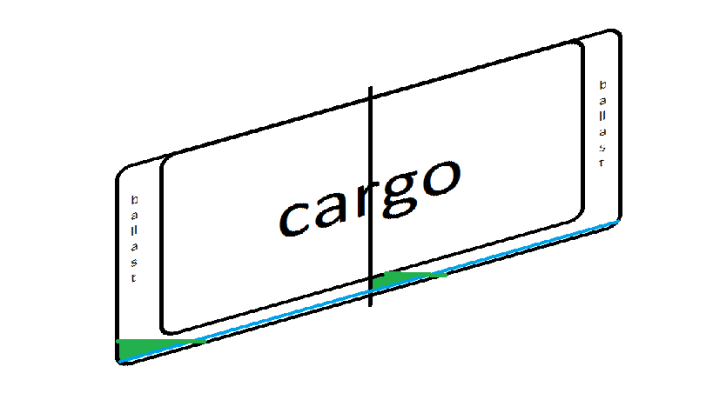

Here is a crude drawing of how free surface affects the list on a barge, and (since there is no pumping ability installed) it necessitates manually hauling pumps around the barge to empty the tanks.

Of course this is simplified, but the method of the barge capsizing is a known event, and when a barge is 'lurching' side to side is a huge warning sign to both crew ON the barge as well as the tug operator to pump the tanks dry.

I don't have pictures, but I flipped a 130' deck barge over, using water ballast in the barge, and one tug pulling the barge sideways, and My tug pulling the barge the opposite way, with the wire bridles wrapped around the side of the barge. The barge slowly tips over on her side, and lays upside down. The deck hatchs with the water in them have water hose suction fittings installed to pump out the water and the barge is flipped. It works the same in reverse, but a diver must be used to remove the hatchs' underwater and install modified hatches with hose fittings to pump water in, or out as needed.

The 'under 200' sized little barges in the gravel trade are made to withstand being grounded while being (un)loaded that it is not a stress issue with them.

However, the free surface inside the tanks (which ARE supposed to be free of water) is often an issue. I have seen several around New York harbor flipped in my career. The water being pumped out is an issue. Keeping it out is another issue. The front barge (Bernoullis' principle) in a tow is susceptible to being constantly head down, thus the forward tanks being full of water.

Here is a crude drawing of how free surface affects the list on a barge, and (since there is no pumping ability installed) it necessitates manually hauling pumps around the barge to empty the tanks.

Of course this is simplified, but the method of the barge capsizing is a known event, and when a barge is 'lurching' side to side is a huge warning sign to both crew ON the barge as well as the tug operator to pump the tanks dry.

I don't have pictures, but I flipped a 130' deck barge over, using water ballast in the barge, and one tug pulling the barge sideways, and My tug pulling the barge the opposite way, with the wire bridles wrapped around the side of the barge. The barge slowly tips over on her side, and lays upside down. The deck hatchs with the water in them have water hose suction fittings installed to pump out the water and the barge is flipped. It works the same in reverse, but a diver must be used to remove the hatchs' underwater and install modified hatches with hose fittings to pump water in, or out as needed.

Attachments

Last edited: