Alaskasbear

Veteran Member

- Joined

- Jun 10, 2016

- Messages

- 58

- Location

- United States

- Vessel Name

- Slow Goin

- Vessel Make

- 78 MS 34 Mk1

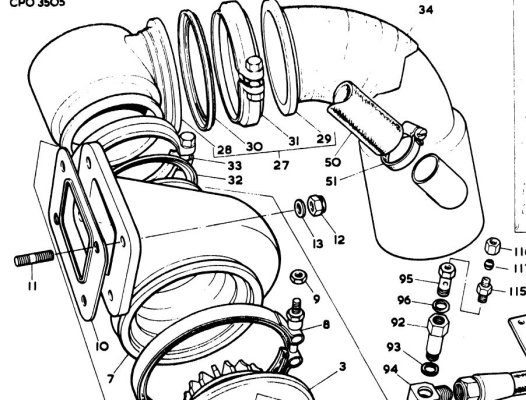

Does anyone have any pictures of Engine room a and different angles of the engine. Looking for what might be missing from mine and maybe ways I could improve on it such as deck plates down alongside the engine to protect transducers and make it easier to stand, rerouting of exhaust flange so it doesnt stick up so obnoxiously etc etc.

If you have some please post them. ALSO any pictures of the raw water pump and strainer assembly, battery layout. Looking to improve.

Here is what I'm working with now. Its a mess.

If you have some please post them. ALSO any pictures of the raw water pump and strainer assembly, battery layout. Looking to improve.

Here is what I'm working with now. Its a mess.