You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New construction: She:Kon

- Thread starter She-Kon

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

She-Kon

Senior Member

Someone suggested a TENS device awhile ago for the carpal tunnel. I picked one up off of FleaBay and have been using it on my back, knee & wrists. What an amazing little device! Used it this morning for 3 x 15 min sessions and the pain in my back was gone! It seems to last for days too!

Anywho, it let me jump around the boat this morning like a mad Roo on crack!

Mocked up the engine beds and will glue them in place tomorrow. Off to pick up my Jeep that's been in the shop for 3 days getting a new clutch! *sigh*

Web log updated: https://she-kon.blogspot.ca/2016/06/tens-stimulating.html

Standby....

Anywho, it let me jump around the boat this morning like a mad Roo on crack!

Mocked up the engine beds and will glue them in place tomorrow. Off to pick up my Jeep that's been in the shop for 3 days getting a new clutch! *sigh*

Web log updated: https://she-kon.blogspot.ca/2016/06/tens-stimulating.html

Standby....

Last edited:

She-Kon

Senior Member

Not my best work but there it is, glued & screwed (temporary) in!

Bedded it in plenty of epoxy glue and used a notched trowel just like they do on tiles. Worked well but squeezed out a lot of the glue when I pushed the pieces into place. Oh well a quick go over with the sander will clean that up!

Bedded it in plenty of epoxy glue and used a notched trowel just like they do on tiles. Worked well but squeezed out a lot of the glue when I pushed the pieces into place. Oh well a quick go over with the sander will clean that up!

She-Kon

Senior Member

Got port side engine bed glued & screwed (temporary) into place this morning. Was going to do some more sanding but I keep getting the uncured glue all over myself.

Going on a hunt to find a 12' step ladder so I can install a pair of ceiling fans in the shed.

Standby...

Going on a hunt to find a 12' step ladder so I can install a pair of ceiling fans in the shed.

Standby...

She-Kon

Senior Member

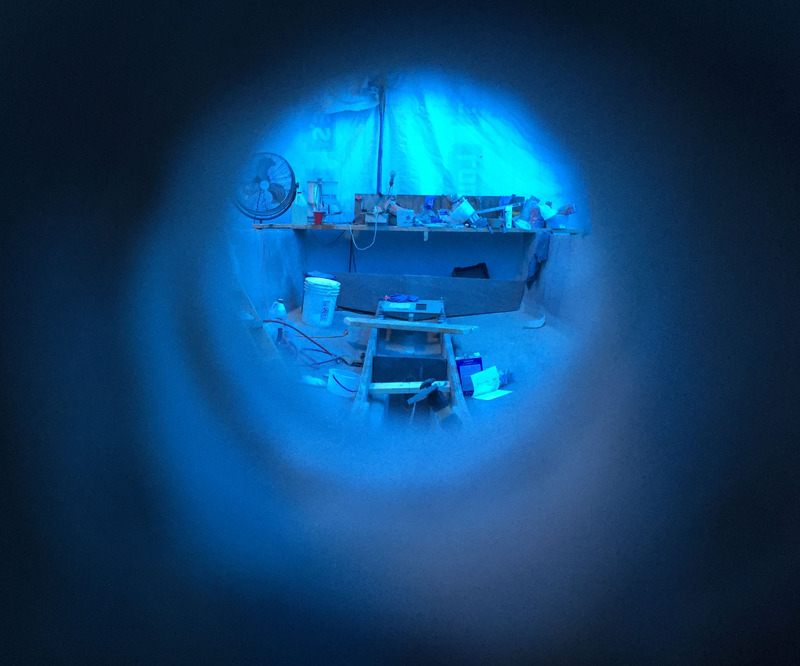

Finally got all the pieces of the puzzle together to get my ceiling fans up in the boat shed.

They make quite a bit of difference!

Other nonsense on the web log update: https://she-kon.blogspot.ca/2016/07/thar-she-blows.html

They make quite a bit of difference!

Other nonsense on the web log update: https://she-kon.blogspot.ca/2016/07/thar-she-blows.html

She-Kon

Senior Member

Still moving in 'a direction' albeit in Slow-Mo-Shun!

Tinkered around with a few things the last few days in between thunder storms, heat & humidity. Engine beds have first layer of glass on them and I've brought a couple of the bulkheads aboard to begin to get them aligned for glue & tape.

Web log updated: https://she-kon.blogspot.ca/2016/07/slow-mo-shun.html

Tinkered around with a few things the last few days in between thunder storms, heat & humidity. Engine beds have first layer of glass on them and I've brought a couple of the bulkheads aboard to begin to get them aligned for glue & tape.

Web log updated: https://she-kon.blogspot.ca/2016/07/slow-mo-shun.html

She-Kon

Senior Member

She-Kon! love the build! I'm on the wooden boat forum too. (same name). Do you post over there? (tough crowd)

gotta love stitch and glue!

Hi Denise. Thanks for looking in.

I used to post over there but the 'tough crowd' chased me away a few years ago. I do check in once in awhile to see what my ole' buddy Peter Lenihan is up to. Unfortunately he's been AWOL for quite awhile now.

Thanks again.

ben2go

Guru

Still moving in 'a direction' albeit in Slow-Mo-Shun!

Tinkered around with a few things the last few days in between thunder storms, heat & humidity. Engine beds have first layer of glass on them and I've brought a couple of the bulkheads aboard to begin to get them aligned for glue & tape.

Web log updated: https://she-kon.blogspot.ca/2016/07/slow-mo-shun.html

Good update Rick.Nice tribute to the family friend.I'm looking forward to watching those frames go in,since you stretched her and all.

Hi Denise. Thanks for looking in.

I used to post over there but the 'tough crowd' chased me away a few years ago. I do check in once in awhile to see what my ole' buddy Peter Lenihan is up to. Unfortunately he's been AWOL for quite awhile now.

Thanks again.

Hi Denise,I'm on Wooden Boat forum to.I was another "kind of chased away" by the Rough crowd.I sometimes go back.I guess I like the abuse.

Rick,I hope Peter gets in contact with you soon.I hope things are getting better for him and Nat.I wanted to send them a little,we're thinking of you guys,gift through the mail,but I am not sure if the address I have is Peter's current address.If I PM the address I have, would you be able to confirm it?

She-Kon

Senior Member

Spent a lot of time hmmmm'ing & hawing today. Bulkheads A & B that you've seen I tried to get lined up by the marks I put on the hull when the thing was upside down on the strongback. Didn't exactly seem to work out quite right and I know why. It was something that happened waaaaaaaaaay back when I assembled the panels. Anywho.....

Had to yank bulkhead E out of the pile and cut it in half so I can install it in the boat first. I'm positive of the position it'll go in the boat and once I get it plumb & squared away I can take my measurements of of it for the remainder of the bulkheads.

Web log update: https://she-kon.blogspot.ca/2016/07/hmmmmmmm.html

Standby...

Had to yank bulkhead E out of the pile and cut it in half so I can install it in the boat first. I'm positive of the position it'll go in the boat and once I get it plumb & squared away I can take my measurements of of it for the remainder of the bulkheads.

Web log update: https://she-kon.blogspot.ca/2016/07/hmmmmmmm.html

Standby...

She-Kon

Senior Member

Spent most of the morning wrestling with the main bulkhead, E, getting it into place, trimmed for fit etc.

Ran out of Jigsaw blades so it's a supply run this afternoon. Mercury is supposed to jump into the mid 30's C with humidex!

Web log updated: https://she-kon.blogspot.ca/2016/07/fighting-dirty.html

Standby...

Ran out of Jigsaw blades so it's a supply run this afternoon. Mercury is supposed to jump into the mid 30's C with humidex!

Web log updated: https://she-kon.blogspot.ca/2016/07/fighting-dirty.html

Standby...

She-Kon

Senior Member

Rick. Don't forget to drink lots of fluids. Nothing sucks worse than a ride to the er for dehydration.

Thanks BC. Oh I'm aware! Ended up in the hosp a month or so ago dehydrated!

Not due to boat shed sauna's though!

Not due to boat shed sauna's though! Thanks for looking in!

Cheers!

She-Kon

Senior Member

You'll be hammerin the lid on this boat in no time.It seems like things pick up after the bulkheads are in, and then slows down again when it's time fur the details.

The whole project comes in fits & starts. It's usually a matter of $$$ or time or energy. All of which seem to be in short supply lately. We've no deadline so it'll get done when it gets done I guess.

Thanks for looking in Ben.

Cheers!

RT Firefly

Enigma

Greetings,

Mr. SK. Have you decided on ballast yet?

Mr. SK. Have you decided on ballast yet?

She-Kon

Senior Member

Greetings,

Mr. SK. Have you decided on ballast yet?

99% sure I'm going with lead and the flexible water tank below the engine as discussed earlier. I've found some scrap steel offcuts that might work if I need more.

She-Kon

Senior Member

Back out in the shed for awhile today to get some stuff done before the heat rises.

Lined up bulkhead E and prepped it for some quick tabs tomorrow. Today's web log update also includes a Season 6 Premiere Youtube video!

https://she-kon.blogspot.ca/2016/07/the ... blood.html

Standby...

Lined up bulkhead E and prepped it for some quick tabs tomorrow. Today's web log update also includes a Season 6 Premiere Youtube video!

https://she-kon.blogspot.ca/2016/07/the ... blood.html

Standby...

Hey rick . I just had a thought. I'm not sure if you have checked into or not. But what about iron filings from an automotive place that does brakes. You could make iron/led ingots. It won't be as heavy as a lead only ingot but it will definitely add to the weight.

She-Kon

Senior Member

Hey rick . I just had a thought. I'm not sure if you have checked into or not. But what about iron filings from an automotive place that does brakes. You could make iron/led ingots. It won't be as heavy as a lead only ingot but it will definitely add to the weight.

Hey BC

The machine shop that's doing my rudder build has an old SS prop shaft from an ancient farm machine. It's about 6" in dia and 13' long. He said he'd cut it up into 1' lengths. Should yield over 1200 lbs. More than I need.

Always looking for options though. You never know when a deal might pop up!

Hey BC

The machine shop that's doing my rudder build has an old SS prop shaft from an ancient farm machine. It's about 6" in dia and 13' long. He said he'd cut it up into 1' lengths. Should yield over 1200 lbs. More than I need.

Always looking for options though. You never know when a deal might pop up!

RT Firefly

Enigma

Greetings,

Mr. SK. GREAT find on the shaft! How about having it cut to the width of your keel cavity and having the axis of the shaft pieces at right angles to the keel? A few wedges to keep the pieces from rolling fore and aft. Looked it up....One foot of 6" SS shaft is about 100lbs.

Mr. SK. GREAT find on the shaft! How about having it cut to the width of your keel cavity and having the axis of the shaft pieces at right angles to the keel? A few wedges to keep the pieces from rolling fore and aft. Looked it up....One foot of 6" SS shaft is about 100lbs.

She-Kon

Senior Member

Mr. SK. GREAT find on the shaft! How about having it cut to the width of your keel cavity and having the axis of the shaft pieces at right angles to the keel? A few wedges to keep the pieces from rolling fore and aft. Looked it up....One foot of 6" SS shaft is about 100lbs.

It is a good find. I've tucked it away for now. Was up the road a bit this morning and just for laughs checked in at the local metal place. They wanted $2.75/lb for scrap lead. Lead I'd have to smelt down into bars. I'd collect wheel weights before I'd pay that price. Anywho, we're still a couple yrs away from having to make those choices.

She-Kon

Senior Member

Main bulkhead tabbed in. I'll finish it up today. I left about a 3/16" gap all around so the bulkhead isn't touching the hull.

Updated the web log. There's another video but it's looooooong! I mysteriously turned into a Chatty Cathy for some reason!

https://she-kon.blogspot.ca/2016/07/ordinary-day.html

Updated the web log. There's another video but it's looooooong! I mysteriously turned into a Chatty Cathy for some reason!

https://she-kon.blogspot.ca/2016/07/ordinary-day.html

RT Firefly

Enigma

Greetings,

Mr. SK. Why the gap betwixt the bulkhead and the hull if the bulkhead will be tabbed to the hull and essentially be part of the hull?

Mr. SK. Why the gap betwixt the bulkhead and the hull if the bulkhead will be tabbed to the hull and essentially be part of the hull?

She-Kon

Senior Member

Greetings,

Mr. SK. Why the gap betwixt the bulkhead and the hull if the bulkhead will be tabbed to the hull and essentially be part of the hull?

It's my understanding, from web research and what the other builders/owners out there are telling me that if the bulkhead touches the hull a sharp bang to the hull in or near that spot can lead to stress & spider cracks. The direct connection of the bulkhead to the hull causes a 'hard spot'. By leaving the bulkhead a lil' bit 'proud' of the surface and large taped fillets you spread out the forces over a much larger area and hence less propensity for cracking.

The stringers are 'bedded' in epoxy glue and do not come into direct contact with the hull. I used very large fillets to increase the surface area.

Anywho, that's my understanding of it anyways. I'll do the rest the same way.

Great question! Thanks for posting.

She-Kon

Senior Member

IIRC bulkheads formerly caused hard spots on the hull that eventually showed up on the outside. Builders added some cushioning to spread the load.

IMO just using tabbing to take the load is questionable

You're absolutely right bayview and the more I wander through the Interwebs researching it the more confused I became. Some advocate leaving a void. Some use high strength structural adhesives, some foam fillers etc.

There won't be any voids in my layup. The bulkheads are not touching the sides or bottom and will have the space taken up by the same epoxy filler I use as glue to make the fillets.

That should distribute any point loading over approx. 2" which is 4 X the width of the panel. Specifications from the designer IIRC are for 3 staggered 6" x 6 oz biax tape. Seeing as this is the main bulkhead dividing the engine space from the accommodations and is approx half way down the hull I'll likely add one extra layer of 8" x 12 oz biax.

I'm mostly 15% to 25% over spec on all my layups so far and these joints won't be any different. The beotch is built like a tank! Of course there's a premium in cost & weight for doing so.

Thanks for looking in. Appreciate the feedback immensely!

Cheers!

ben2go

Guru

Good update.I never thought about the bulkheads causing hard points and possible future cracking.The couple boats I've helped with where small, and probably weren't subjected to the stress, that a large hull like yours, may encounter.

Similar threads

- Replies

- 1

- Views

- 468

- Replies

- 3

- Views

- 746

- Replies

- 14

- Views

- 786