3rd season on the boat. Age of anchor rode unknown, 100' chain, 200' nylon. The first 50' feet of nylon has mild chafe, so I swapped the nylon end for end, which now looks and feels like new line. Went over to youtube and watched a few videos on making an eye splice with thimble. First attempt was ugly, had a few out of sync points, but wrapped many more than the recommended 5-7.

Tested at anchor in 50' of mud overnight, wind 5 to 0kt thought the night. Full 360 swing several times. Next norming the splice looks the same, but the original braid above the splice came apart.

Cut the line back 3' and spliced a second time, tested overnight night at anchor again. Same issue. A 3rd night with the same splice did not untwist any more braid. What is the cause?

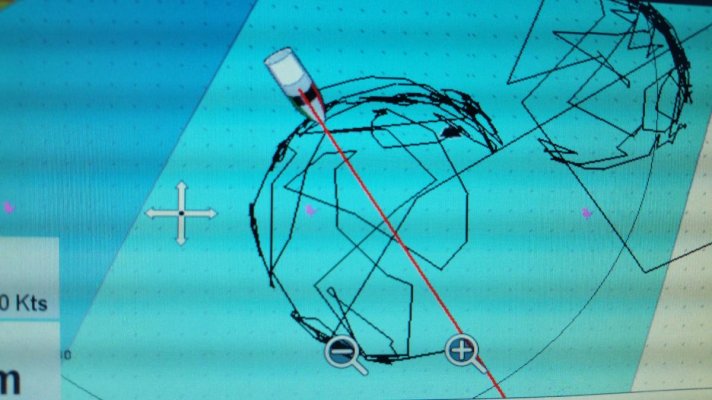

Photos are of second attempt. We did not swing a full 360 on the second night.

Tested at anchor in 50' of mud overnight, wind 5 to 0kt thought the night. Full 360 swing several times. Next norming the splice looks the same, but the original braid above the splice came apart.

Cut the line back 3' and spliced a second time, tested overnight night at anchor again. Same issue. A 3rd night with the same splice did not untwist any more braid. What is the cause?

Photos are of second attempt. We did not swing a full 360 on the second night.