Can you provide a link or something where you get that kind of electric priming pump & does it go between tank & inlet of primary pump?As Baker discovered "priming" and "removing/ bleeding air" are two different things. It is much easier using an electric priming pump rather than manual to bleed the air, but I don't think any diesel engine likes air on the fuel side.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuck at Dock-fuel filter problem?

- Thread starter RickyB

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

ulysses

Guru

Markpierce: Max consumption of 4 gph but what is your max passing through your filter ? In other words how much passes through your filter and then is returned ? This amount added to what is consumed or burned by the engine is the amount necessary to be filtered.

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,195

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Markpierce: Max consumption of 4 gph but what is your max passing through your filter ? In other words how much passes through your filter and then is returned ? This amount added to what is consumed or burned by the engine is the amount necessary to be filtered.

Add to the above valid comment the decreasing flow rate as the filter does its job. Not too relevant though for those that only consume a few hundred gallons per year.

Ski in NC

Technical Guru

Racor 500's will be fine for those engines and expected duty cycle. Downside is they can't hold as much gunk before clogging, but if clogging is infrequent, not a big deal.

If there is some mobile crap in the tank randomly clogging the pickup, that will show on a racor vacuum gauge.

If there is some mobile crap in the tank randomly clogging the pickup, that will show on a racor vacuum gauge.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Markpierce: Max consumption of 4 gph but what is your max passing through your filter ? In other words how much passes through your filter and then is returned ? This amount added to what is consumed or burned by the engine is the amount necessary to be filtered.

Four gallons is the net consumption of the engine. I don't know how much fuel running through the filter is returned to the fuel tank. (JD 4045 NA engine)

CPseudonym

Moderator Emeritus

Four gallons is the net consumption of the engine. I don't know how much fuel running through the filter is returned to the fuel tank. (JD 4045 NA engine)

Tier II compliant 80 or 85 HP if I recall properly as the 4045 comes in a variety of HP ratings. I had the JD shop manual for your engine in pdf format on my old computer but cannot find it now.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Eighty hp

PS - fuel consumption is 1.5 to 2.0 gallons at normal cruising speeds.

Believe the four-gallon consumption rate is at 2500 rpm, but the governor is set for a maximum of 2400.

PS - fuel consumption is 1.5 to 2.0 gallons at normal cruising speeds.

Believe the four-gallon consumption rate is at 2500 rpm, but the governor is set for a maximum of 2400.

Last edited:

The last sentence was suppose to ask if the electric priming pump goes between tank & primary Filter.Can you provide a link or something where you get that kind of electric priming pump & does it go between tank & inlet of primary pump?

Bay Pelican

Moderator Emeritus

Can you provide a link or something where you get that kind of electric priming pump & does it go between tank & inlet of primary pump?

The Walbro FRB13 (30 US gallons per hour) is in standard use on boats as both a priming pump and electric fuel (diesel) pump.

Depco and others sell this pump.

Heron

Guru

- Joined

- Nov 5, 2014

- Messages

- 1,304

- Location

- USA

- Vessel Name

- Heron (2)

- Vessel Make

- '88 Cape Dory 28 Flybridge #115

The last sentence was suppose to ask if the electric priming pump goes between tank & primary Filter.

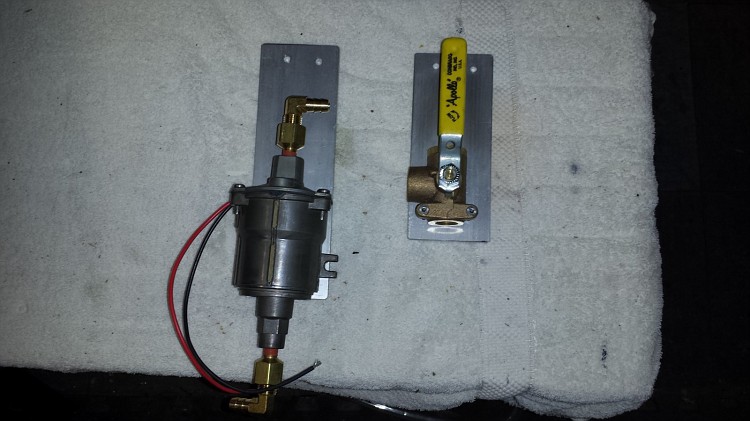

I put a real simple system in. It allows priming, recirculating (filter/polish) and tank to tank balancing. Inexpensive to do too... ($200 or so with pump and plumbing). I generally leave the pump off as it is a flow through, but have it switched to accomplish any of the above functions. (and yeah, I have a lot of filtration). The big cannister Fleetguard seems to be the most important as it will grab a ton of junk without clogging. 3 others downstream keep everything clean and waterfree.

pump selection: http://www.fuel-pumps.net/frseries.html

Last edited:

ranger58sb

Guru

Thank you sunchaser. I've been thinking that for a while. The crazy thing is at West Marine they want about $15-16.00 for the 500 series element. I saw the Racor 1000 series elements next to those for only $19.95. The 1000 series looks like they have 4 time the area for $4.00 more.

The size and raw materials probably isn't the main cost factor for producing those. That could be something like the manufacturing process, labor, etc. For example, it probably costs the same labor rate to pay the guy running the macking making 500 elements as it does to pay the guy making 900 or 1000 elements.

I was thinking exactly that. Both 150 gal tanks are 3/4 full so that's over 100 gals to pump somewhere. The good things is it's all fresh fuel. I don't know what to come up with to store pumped fuel in.

Maybe you can find another guy with an empty tank truck? Pump to that, clean your tanks, refill from the truck?

-Chris

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

The most common container is a 50G drum , or an old fruit juice plastic container.

With a day or two of standing , esp with a 2x4 under one side to create a low spot , most of the fuel can be syphoned back into the fuel tank, with only a clear plastic tubing to guide you from the water..

Any fuel company has a paste that can be put on a stick to give you the water depth in the barrel.

IF you need to pump the bad fuel be sure to suck thru a filter , not pump thru it.

With a day or two of standing , esp with a 2x4 under one side to create a low spot , most of the fuel can be syphoned back into the fuel tank, with only a clear plastic tubing to guide you from the water..

Any fuel company has a paste that can be put on a stick to give you the water depth in the barrel.

IF you need to pump the bad fuel be sure to suck thru a filter , not pump thru it.

Ski in NC

Technical Guru

Blue barrels available all over the place. Got some from a car wash, they held soap. Still had to rinse them out, once done, nice and clean. Most towns have vendors that collect, clean and sell drums.

Cleanest barrels on the planet are some I got from a local boat builder. Acetone drums, absolutely shiny inside. But steel, so a little less friendly to the boat world.

Do not try to clean out resin drums. Useless for fuel and it takes more acetone to clean them than they are worth. Resin drums only good for burn barrels and boy that first burn rocks and rolls!! Caveat: For country living only.

Regarding fuel pump, a Facet 40185 is a handy low cost generic 5psi diesel pump. I try to keep one around.

Cleanest barrels on the planet are some I got from a local boat builder. Acetone drums, absolutely shiny inside. But steel, so a little less friendly to the boat world.

Do not try to clean out resin drums. Useless for fuel and it takes more acetone to clean them than they are worth. Resin drums only good for burn barrels and boy that first burn rocks and rolls!! Caveat: For country living only.

Regarding fuel pump, a Facet 40185 is a handy low cost generic 5psi diesel pump. I try to keep one around.

Thank you. I did see the fuel polisher where the gear pump sucked dirty fuel through a screen filter, through pump, & then 10 micron filter back to tank.The most common container is a 50G drum , or an old fruit juice plastic container.

With a day or two of standing , esp with a 2x4 under one side to create a low spot , most of the fuel can be syphoned back into the fuel tank, with only a clear plastic tubing to guide you from the water..

Any fuel company has a paste that can be put on a stick to give you the water depth in the barrel.

IF you need to pump the bad fuel be sure to suck thru a filter , not pump thru it.

Thank you for drum & pump info. Now I can see & learn more from these examples.Blue barrels available all over the place. Got some from a car wash, they held soap. Still had to rinse them out, once done, nice and clean. Most towns have vendors that collect, clean and sell drums.

Cleanest barrels on the planet are some I got from a local boat builder. Acetone drums, absolutely shiny inside. But steel, so a little less friendly to the boat world.

Do not try to clean out resin drums. Useless for fuel and it takes more acetone to clean them than they are worth. Resin drums only good for burn barrels and boy that first burn rocks and rolls!! Caveat: For country living only.

Regarding fuel pump, a Facet 40185 is a handy low cost generic 5psi diesel pump. I try to keep one around.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"I did see the fuel polisher where the gear pump sucked dirty fuel through a screen filter, through pump, & then 10 micron filter back to tank"

Thats a very poor setup as the mechanical gears will mix the fuel and water into a very fine mixture which is harder for the filter to trap.

Would be OK if just removing crud , but for water removal UGH.

Thats a very poor setup as the mechanical gears will mix the fuel and water into a very fine mixture which is harder for the filter to trap.

Would be OK if just removing crud , but for water removal UGH.

Similar threads

- Replies

- 5

- Views

- 901