Ted,

You've raised more questions than answers.

Details details details or it's just a few pictures.

How do they get from the redish brown stuff that looks goopy to the smooth white. And if by sanding how does one avoid ending up w ridiculously thin overcoat or sanding right through??....

78puget,

I know the difference but hand rails get scuffed up too. Probably not so much from feet but dragging stuff over them ... perhaps tool or boxes of stuff. Same issue .. when the hard scuff resistant coatings crack water gets to the teak and under the coating. That results in black stains and the water slowly spreads out and lifts off the coating. My experience has been that flexability is more important than hardness. Add touch up friendliness to that preference as well.

Good God! Did they put that filler on with a hair comb or a wire brush?

And why not just seal the rails with clear epoxy and then prime and paint?

The Process: The teak was sanded down so that the West System would soak into clean wood and the finished product would be approximately the same size as the original cap rail. The caulk was removed between the teak and the fiberglass it was attached to. A slot was formed where the caulk was so the bi-axial cloth with WS could be tucked under the teak cap rail. After the cloth was applied and tucked, a WS with bonding filler additive was applied as a filet to bond the cloth to the fiberglass below the cap rail and fill the remaining slot space. Finally, WS with fairing additive (West System frosting) was applied with a paint brush. From wetting out the teak with WS, through applying the cloth, tucking, and filleting, to applying the frosting, all the steps were done in one day so that all the WS would bond and cure together.

Sanding, shaping was done by a pro, Sean, so that there would be no sanding through the bi-axial cloth. The object was to have very little of the frosting left as it's only to fill the cloth print voids. The process encapsulated the teak and gave it a barrier (the cloth) much stronger and more puncture resistant than simply applying multiple coats of WS and painting over it. After the sanding was completed, the cap rail (and the rest of the boat) recieved 2 coats of Awlgrip primer, was sanded, and then 2 to 4 coats of Awlgrip Ultra Build. The white you see in the picture is the Ultra Build which is the final fairing stage for that perfect smoothness. After the Ultra Build is sanded, 2 more coats of Awlgrip primer sealer, sand lightly again, and then 2 coats of Awlgrip top coat.

What I ended up with is a surface as durable as the hull with a 15+ year projected life for the paint. There will likely be hard wear areas that may need to be repainted. Most likely it will be sanding, repriming, and top coating. Same as repairing scratched paint over fiberglass.

If you look carefully, you can see the teak rub rail below the cap rail. That was also encapsulated, but with 2 layers of bi-axial cloth with WS to be even more durable.

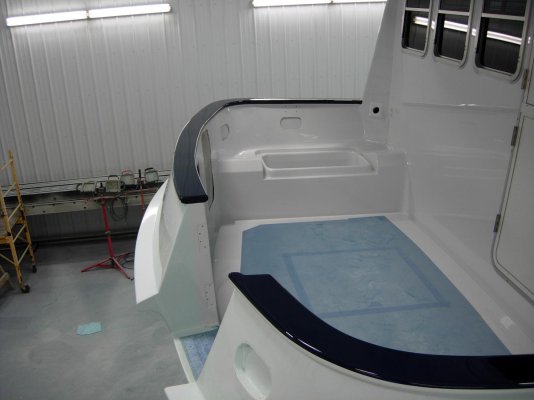

This is the transom door after everything through the fairing of the Ultra Build. It's ready for final priming and top coating.

After the top coat, but before the Stainless steel rub stake that covers the exterior paint line.

Ted