"To help us out in putting all the pieces together, and to keep you busy while waiting on a mechanic, take some time and develop a complete timeline of exactly what was done to the engine, what symptoms showed and when, and the engine running details such as rpm and noise in between steps of work. Be concise, but leave out no details. Piecing it together from thread posts leaves gaps."

Here you go-

3208 Timeline

May 5- The boat became mine a couple days ago so I decide to change the oil and all filters, along with all the fuel filters and engine zincs. My goal was to change everything (belts, water impellers, coolant, tranny fluid, whatever else I could get my hands on but no main bearings or rods!). At this point there was 1605 hours on starboard engine.

Mid May, a CAT mechanic that was in town came and took a look at the motors because I was a little concerned about a fuel leak from the throttle shaft seal on both engines. He confirmed what several others have told me- it’s something that should be fixed sooner than later but nothing catastrophic will happen, just wasting fuel from the leak

Over the first 6 weeks or so after we bought it, we put about 110 hours on the engines. Going long distances, short distances, trolling, sightseeing, fast slow, etc...No knocks, no unusual noises, but I do have to prime the fuel and purge the air from the bad seals. Otherwise, everything seemed good. I pay very close attention to the gauges I have (oil pressure, fuel, and water temp) every time we go out and they never go out of range. I always check the oil and coolant levels before going out. Every once in a while I have to add some oil but not huge amounts. The oil pressure is always good, according to the gauges, so I was hoping to make it a winter project.

June 21- The boat is loaded up and we’re ready to start the family vacation. Engines have been running in the harbor and are warmed up. We go a few hundred yards to fuel up and after getting fuel, I restart the motors and notice more white smoke than I remember seeing before coming from the starboard side and make a mental note to pay closer attention. About 20 or 30 minutes later, I was going a little faster than cruising speed to make up for lost time but nothing extreme. Then all of a sudden I hear a very loud knocking sound. I immediately pulled back on both throttles and put both engines in neutral. I turn off the port motor, knock continues. I turn off the starboard motor and knock goes away. I ask my wife to restart the starboard motor while I go to the ER to see if I can find anything obvious. There was a lot of smoke and the fuel leak was pretty excessive, worse than it’s been, and the knock started right away and was loud enough to make me very nervous so I signaled to my wife to turn it off right away. I think the fuel was on the exhaust manifold, so maybe this is a blessing in disguise- I don’t know if it would get hot enough to ignite or not?? I didn't think so, but maybe I was wrong

We limped out on the port motor to a nearby cove and anchored up for the night in order to try to make the trip not be a complete loss. I started the motor the next morning and the knock was still there so I turned it right off. On the way back in, I talked to my friends wifes uncle (ever see Ferris Bueller? Anyone? Anyone?) who is not a mechanic but a fisherman that has had CATs for years. His recommendation is to fix the fuel leak first since I know that problem exists. Unfortunately fishing season is here so all of the people that know about these things are either booked solid or out fishing. The great news is that after I put in the new seal, it doesn’t leak or need priming anymore, so the seal fix worked for that. But the knock is still there. This brings me to June 24th when I came to the forum I have learned to trust and love, and hopefully contribute to someday instead of just leach info from all of you...

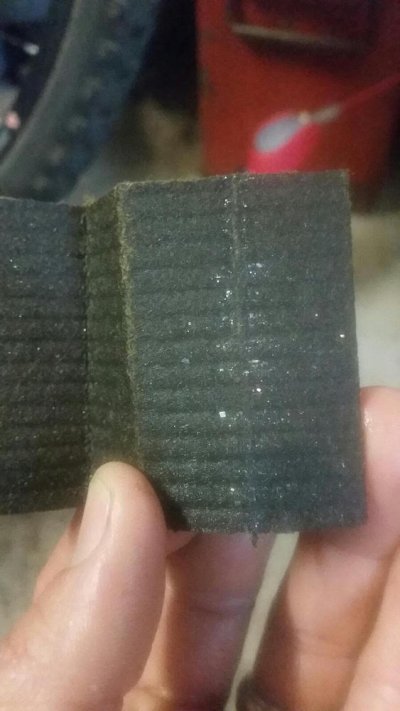

I got directions on how to replace the throttle shaft seal from boatdiesel, and it didn’t mention removing any fuel lines, so I didn’t. It wasn’t easy to get the air intake manifold off that way but it worked. Thats how I’ve been able to crack open injector bolts and try to do other diagnostics you all have mentioned since I originally posted. I have kept the intakes covered up when not on the boat and I am confident that nothing has fallen in, but this all started before any of that was ever removed anyway. I tried listening with a screwdriver, cracking injector lines, and correcting valve lash (twice). I have posted here, boat diesel, and paid for an opinion on justanswer.com, been on the phone and email with the CAT shop, had a couple of pseudo-mechanics offer opinions, talked to experienced boaters at work, and anything else I can do. I am in the process of looking for a lab to get oil analyses but ran out of time before I head out of town tomorrow morning. To be honest, I don't have a lot of faith in the shop that says I need to spend 35k without even seeing the motor. This is the same shop that said the motors were fine 7 weeks ago. I'm not saying they're crooked, but I'll probably get a 2nd opinion before going back to them. After everything lead to dead ends, I pulled the oil filter and found the flakes. I have not started it since then, nor do I plan to. Tonight I tried to drop the oil pan only to learn that the forward motor mount bracket is in the way. I have to go down to Klawock for work for the next 10 days and when I get back there’s a mechanic that wants me to give him a call so he can try to come take a look. Hopefully while I’m gone I can learn how to jack up my motor enough to remove those bolts without sending a jack through the bottom of the boat!

I don't know the RPMs because my tachs don't usually work. I try keep it around 7-9 knots and adjust the throttle so it sounds even. This is what I have seen from the PO, the surveyor, and the broker from another vessel I had surveyed in WA. When the knock started, I was probably closer to 12 knots. WOT gets me to about 17-18. The knock knocks at all RPMs, whether in neutral or in gear. If you would like any other info, let me know and I'll do my best.