You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heat exchanger cleanout

- Thread starter wenders

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

RT Firefly

Enigma

Greetings,

Welcome aboard. How does the HE look?

Welcome aboard. How does the HE look?

my lehman 135 is running slightly hot. I took the heat exchanger off and would like to clean it out. Any suggestions on how best to do this?

Rydlyme...

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Put it back in place and flush it with Barnacle Buster for 4 hrs. It solved my heat rise to 190-195*. Now it runs 165-170*. I couldn't be more pleased.

Take the end caps off and with a heavy brazing rod or a 22 cal rifle cleaning rod, push through all of the tubes to open them up. Then either reinstall and circulate Rydlime or Barnacle Buster through them as indicated above, or you can fill the tube side on the bench with those products and let it soak for a while.

David

David

petdoc4u

Senior Member

- Joined

- Jan 14, 2016

- Messages

- 134

- Location

- United States

- Vessel Name

- EXILE

- Vessel Make

- HANS CHRISTIAN TRAWLER

What temperature do you consider to be "slightly hot?"

Since you have it off, take it to a radiator shop for cleaning.

How old is the heat exchanger? It has a finite life and is readily available for around $600.

How old is the heat exchanger? It has a finite life and is readily available for around $600.

Capt.Bill11

Guru

My Lehman 135 is running slightly hot. I took the heat exchanger off and would like to clean it out. Any suggestions on how best to do this?

You shouldn't have taken it off. You can flush the entire raw water cooling system by leaving all the coolers on and flushing through them.

You just need a bucket, pump, hoses and a couple of fittings.

You can use Rydlime, Barnacle Buster, muriatic acid, etc.

Capt.Bill11

Guru

Put it back in place and flush it with Barnacle Buster for 4 hrs. It solved my heat rise to 190-195*. Now it runs 165-170*. I couldn't be more pleased.

165-170 is a bit to cold IMO. 180 is what I like to see a Lehman run at.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

My engines are Perkins 4.236's. The lower helm indicates 165-170, the FB gage shows 5 degrees warmer. I'm OK with that.

They say a man with a watch always knows the time. A man with two watches is never quite sure.

They say a man with a watch always knows the time. A man with two watches is never quite sure.

Capt.Bill11

Guru

What's a temp gun or mechanical gauge say?

Constant low temps are not the best thing for most diesels.

Constant low temps are not the best thing for most diesels.

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,061

I believe Bob Smith says 170 F with a mechanical gage at the expansion tank for a 120 Lehman.

My temp gun verifies.

Mine runs right there, but shows 175-180 on the sending unit gages.

(higher number on the bridge prob due to long old wires).

How about a man with 3 watches? LOL

We have several old pendulum clocks at home. We don't run them. Right now they show the correct time twice a day.

My temp gun verifies.

Mine runs right there, but shows 175-180 on the sending unit gages.

(higher number on the bridge prob due to long old wires).

How about a man with 3 watches? LOL

We have several old pendulum clocks at home. We don't run them. Right now they show the correct time twice a day.

tracie

Veteran Member

- Joined

- Jul 2, 2011

- Messages

- 41

- Vessel Name

- Miss Maggie

- Vessel Make

- 1990 Grand Banks 36

Just removed our heat exchanger from our FL 135 for cleaning - ordered 2 rubber end caps and pencil zincs from American Diesel - as stated in the engine manual, use a 3/16 " wood dowel on each tube -.i used a 10 % solution of muriatic acid and it cleaned up great - new coat of paint - checked all the hoses while reinstalling - good for at least another 1000 hours

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

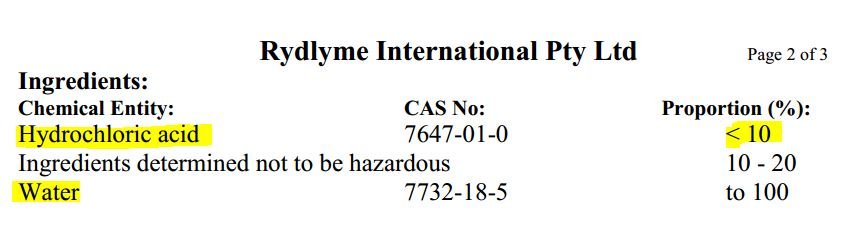

Pretty sure the other 10% is an inhibitor to protect the metal. That would be the proprietary part.

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

If I am not mistaken, after the system is flushed of googlies and drained it gets filled back up with coolant choc full of inhibitor goodness anyway.Pretty sure the other 10% is an inhibitor to protect the metal. That would be the proprietary part.

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

The inhibitor is included in the formula to prevent metal loss DURING the cleaning. Hydrochloric acid is very corrosive without it. Ben

Straight Hydrochloric is but we are talking around 10 % or less for an hour at most.

I believe when you send steel off to get galvanised it goes in a hydrochloric bath of around 10% and sits for several hours. If it was that corrosive I doubt they would use it, especially for structural components.

I may be wrong.

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

Depends on the metallurgy of your heat exchanger. Copper, and most copper alloys, no problem. But any contact with ferrous metals, HCL creates ferric chloride which can pit the base metal fairly quickly. Like "as you watch" quickly.

All I can get out of the chemical rep (Nalco) is that HCL is typically inhibited with an organic cation.

So if you pull your exchanger bundle and you are sure that its metallurgy, (tubes, tube sheets and brazing filler) are compatible, sure go ahead. But if you are flushing while in place, I'd reconsider. High risk? Probably not. But low reward. For a few bucks more, I'd want an inhibited acid cleaner.

Barnacle buster, which I believe is Phosphoric acid, is probably safer anyways.

I'm not a chemical guy what so ever. But I have seen operations groups, trying to save money or time, due considerable damage to vessels, boilers, and heat exchangers while chemically cleaning them. I'm the maintenance guy who gets to repair the mistakes...

All I can get out of the chemical rep (Nalco) is that HCL is typically inhibited with an organic cation.

So if you pull your exchanger bundle and you are sure that its metallurgy, (tubes, tube sheets and brazing filler) are compatible, sure go ahead. But if you are flushing while in place, I'd reconsider. High risk? Probably not. But low reward. For a few bucks more, I'd want an inhibited acid cleaner.

Barnacle buster, which I believe is Phosphoric acid, is probably safer anyways.

I'm not a chemical guy what so ever. But I have seen operations groups, trying to save money or time, due considerable damage to vessels, boilers, and heat exchangers while chemically cleaning them. I'm the maintenance guy who gets to repair the mistakes...

MurrayM

Guru

Haven't been able to source Barnacle Buster in Canada, and the nearest source for Rydlyme Marine I could find is in Vancouver, BC.

Can you find this stuff (or an equivalent product) anywhere else in Canada?

Can you find this stuff (or an equivalent product) anywhere else in Canada?

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

I use pickling vinegar, wooden dowels and gun cleaning brushes. Never had the buildup they get down in the SE states.

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

A few being $150 more of them here.

I'll pop up the road and see what the guys at Diecon eng. Core cooling are using in their big bath.

That's ridiculous. Good idea. Call your local boilermaker fab shop or radiator shop.

questionmark

Senior Member

Haven't been able to source Barnacle Buster in Canada, and the nearest source for Rydlyme Marine I could find is in Vancouver, BC.

Can you find this stuff (or an equivalent product) anywhere else in Canada?

Phosphoric acid is the ticket. I flushed the entire cooling system on my sailboat with it, and the water flow difference was astounding.

The easiest place to get it is at a stone or tile store. They sell it as a grout cleaner. Way cheaper than Barnacle Buster. I used a five gallon bucket from HD and a little pump and tubing to circulate the "grout cleaner."

It takes quite a while longer than the muriatic acid, as it's much weaker.

many years ago, in blissful ignorance, I flushed a pair of my Heat Exchangers with muriatic acid. undiluted. It did a superb job, in very little time. I had recalled a demonstration done in jr high of copper being cleaned with muriatic acid, so I followed what I recalled of the teacher's procedures, paying close attention to the part that kept the acid from my hands and clothing. I never had to take those HEs apart again, had no leaks. They were good when I sold the engines wearing them. Now that I have you guys looking over my shoulders I would not be that brave again.

I might try a solution of Muriatic acid and water though. Now which way do you do the dilution? Acid into water, or water into acid? I know one way is benign, the other is explosive.

I might try a solution of Muriatic acid and water though. Now which way do you do the dilution? Acid into water, or water into acid? I know one way is benign, the other is explosive.

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

I should point out the the rest of the civilised worldmuriatic acid

We mostly use the metric system as well that is, everyone bar Liberia , Burma (Myanmar) and the USA

No offence intended

BruceK

Moderator Emeritus

- Joined

- Oct 31, 2011

- Messages

- 13,347

- Vessel Name

- Sojourn

- Vessel Make

- Integrity 386

The faded recollection from my High School chemistry classes (in Australia) is that muriatic acid is a diluted form of hydrochloric acid.