cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

Did a search but didn't find anything...

It's time for the annual impeller change on my Yanmar. My first change was done by a Yanmar tech but this time I'm going to tackle the job. I did a search on the net, and some folks recommend removing the entire seawater pump due to poor access to the impeller after removing the cover.. The front of the engine sits close to a bulkhead, so you basically have to do everything by feel. And the alternator is in the way.

I found a little Yanmar puller that some have used to successfully get the impeller out. Has anyone here had success with this thing?

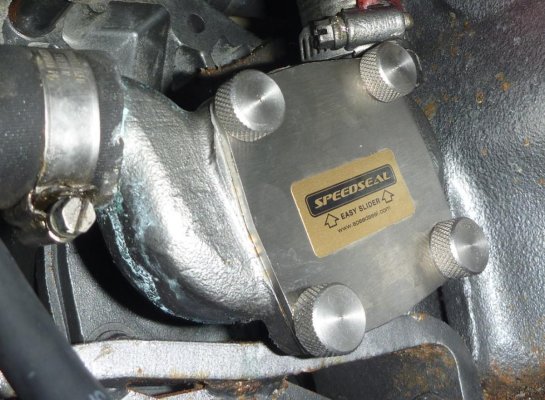

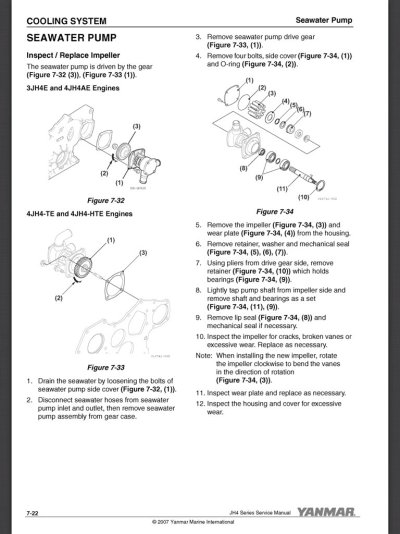

This is what the pump looks like. Would be easy if I could get to the front of the engine!

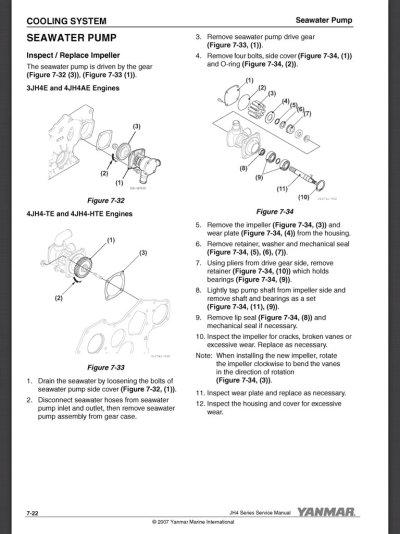

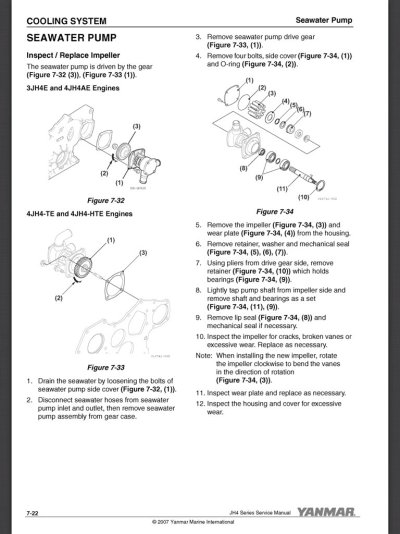

The service manual says to remove the pump...

I've read that many folks have had lots of trouble getting the impeller out and also getting the O ring to seat once they get the new impeller in due to the inability to see what you are doing. So I'm wondering if I should just remove the entire pump. It looks like four bolts to get the pump off, but then I wonder about creating an oil leak or causing some other problem.

Ideas? Anyone done this by feel before?

It's time for the annual impeller change on my Yanmar. My first change was done by a Yanmar tech but this time I'm going to tackle the job. I did a search on the net, and some folks recommend removing the entire seawater pump due to poor access to the impeller after removing the cover.. The front of the engine sits close to a bulkhead, so you basically have to do everything by feel. And the alternator is in the way.

I found a little Yanmar puller that some have used to successfully get the impeller out. Has anyone here had success with this thing?

This is what the pump looks like. Would be easy if I could get to the front of the engine!

The service manual says to remove the pump...

I've read that many folks have had lots of trouble getting the impeller out and also getting the O ring to seat once they get the new impeller in due to the inability to see what you are doing. So I'm wondering if I should just remove the entire pump. It looks like four bolts to get the pump off, but then I wonder about creating an oil leak or causing some other problem.

Ideas? Anyone done this by feel before?

Attachments

Last edited: