Goldenstar38

Senior Member

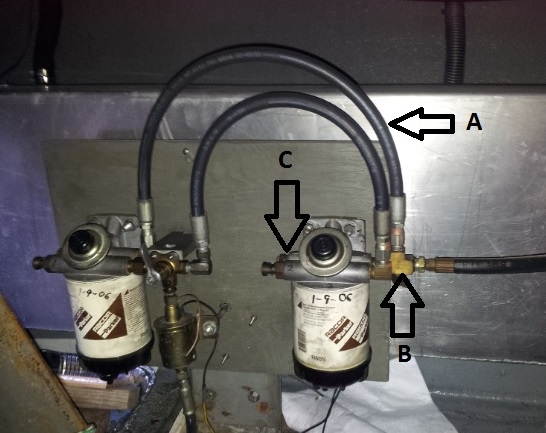

Question: Do the lift pumps used on Perkins engines have a 1 way check valve, so as to keep fuel from backflowing when bleeding and I keep pumping the lever, or do these systems bleed like you would brakes on a car, apply pressure, open the bleeder valve and repeat?

I have looked at previous posts and it appears both methods may have been used. Having difficulty getting fuel to the engine filter (vent on top of housing cracked open) before the CAV pump. My first time doing and a bear, to be polite!

Any tricks, other than a primer bulb or electric pump?

Appreciate the advice. Thanks!

I have looked at previous posts and it appears both methods may have been used. Having difficulty getting fuel to the engine filter (vent on top of housing cracked open) before the CAV pump. My first time doing and a bear, to be polite!

Any tricks, other than a primer bulb or electric pump?

Appreciate the advice. Thanks!