raymond.goff

Veteran Member

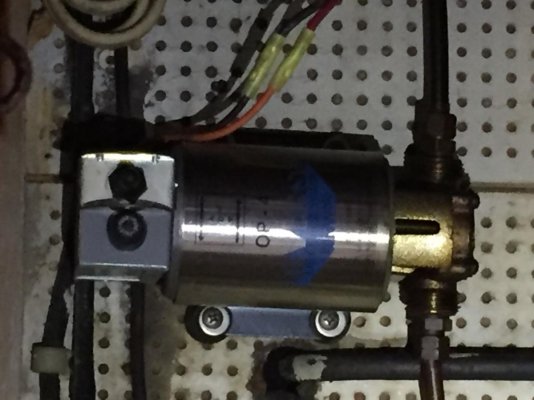

Now that it's warming up, I am starting to crawl through my new to me trawler a bit more. I crawled to the back of the engine room, to look at my filters, and found a device I was not familiar.

I believe it's a fuel polishing system, but I'm not sure which way to turn the handles and how do use?

Since I did not get this from the previous owner, but rather a marina that was in the process of restoring, I have no one to ask how the fuel set up works. In the current configuration the engine runs.

Sent from my iPad using Trawler Forum

Raymond Goff

1978 Marine Trader 34

Our Trawler – m/v Liberty – Travels of a 1978 Marine Trader 34 DC

I believe it's a fuel polishing system, but I'm not sure which way to turn the handles and how do use?

Since I did not get this from the previous owner, but rather a marina that was in the process of restoring, I have no one to ask how the fuel set up works. In the current configuration the engine runs.

Sent from my iPad using Trawler Forum

Raymond Goff

1978 Marine Trader 34

Our Trawler – m/v Liberty – Travels of a 1978 Marine Trader 34 DC