Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

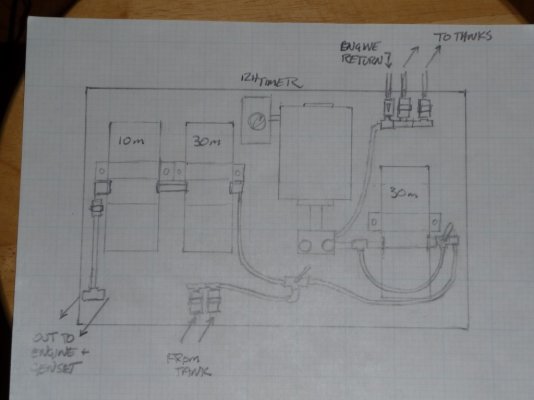

I wanted to start a new thread to have a single point of reference to chronicle and ask questions in regards to my current fuel system upgrade project. As posted in the fuel polishing thread, I am going to reconfigure Skinny Dippin's entire filter rig to be a multi-stage filtration and add a simple fuel polishing circuit.

The current system (I had pics, but the camera got stolen with them in the card) was two Racor 500 filters (and an Algae X). One filter was dedicated to the main engine and the other for the genset. The return line from the main engine dumped into one tank and the genset into the other thru 1/8" (or 3/16") fittings.

I spent this weekend dismantling the old system and now have a pile of parts in the dining room. It, of course, can apart very easily. Now the hard part begins.

The plan is to mount the entire system to a 1/2" piece of Starboard 20"x35" for easy removal and service. Currently, I have received a new Raycor 500 from Defender and a 1/4 horsepower A/C motor, Procon 60 gph pump, and a check valve from Grainger. I have also found two hydraulic shops (one here at home and one down at the boat) that have warehouses of parts and the willingness to help with my project.

I'll take pictures along the way and hope you guys can offer up some good advice.

Thanks,

Tom-

The current system (I had pics, but the camera got stolen with them in the card) was two Racor 500 filters (and an Algae X). One filter was dedicated to the main engine and the other for the genset. The return line from the main engine dumped into one tank and the genset into the other thru 1/8" (or 3/16") fittings.

I spent this weekend dismantling the old system and now have a pile of parts in the dining room. It, of course, can apart very easily. Now the hard part begins.

The plan is to mount the entire system to a 1/2" piece of Starboard 20"x35" for easy removal and service. Currently, I have received a new Raycor 500 from Defender and a 1/4 horsepower A/C motor, Procon 60 gph pump, and a check valve from Grainger. I have also found two hydraulic shops (one here at home and one down at the boat) that have warehouses of parts and the willingness to help with my project.

I'll take pictures along the way and hope you guys can offer up some good advice.

Thanks,

Tom-