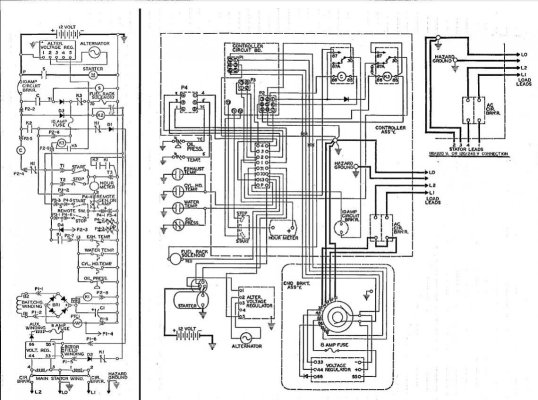

Just to recap the process, on the Kohler 4CCO and many other similar generators, when the start switch is pressed, a number of things happen, 4 of which are:

1. The starter solenoid is energized to engage the starter

2. The fuel shut-off solenoid valve is energized in the 'run' position

3. The engine safety shutdown circuit is bypassed

4. The generator windings are energized so that it can produce AC power

Most of this is a function of the controller board.

Once the engine begins to run and the generator produces 120VAC:

1. The starter solenoid is disengaged, even if the starter switch is still being depressed

2. The engine safety shutdown circuit is energized which now provides

power to the fuel shut-off solenoid valve and maintains it in the 'run' position

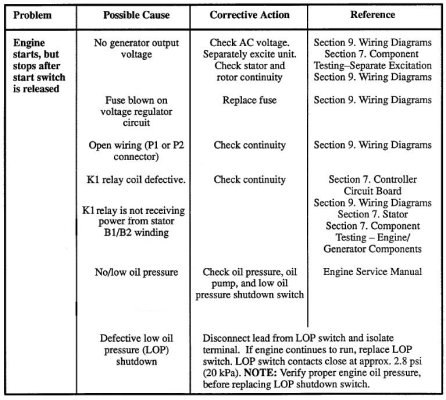

If while running, any of the 4 sensors close (become grounded), the safety shutdown will interrupt power to the fuel shut-off solenoid valve and stop the engine. Further, if the generator stops producing 120VAC, it will also trigger a shutdown. Again, the controller board, two external relays, a diode, a fuse and a circuit breaker control these functions.

When stopped, the 3 temp sensors sensors are 'NO (normally open)' and the OP switch is 'NC (normally closed)'. These can easily be checked with ah ohmmeter. To check them, you must remove the corresponding sensor wire because they are all wired in common. The engine should be at or below operating temperature for the test.

If those simple tests don't reveal the problem, the troubleshooting section in the Kohler 4CCO Service Manual should help. If you need one, PM me and I will send you a PDF.

If it turns out to be the controller board,

Flight Systems, Inc. can quickly rebuild it for a nominal price.

If I had known about the mods Kulas44 mentioned, and had the ability to install them, I surely would have 'pulled all of that old $hit' out and used more modern components to rebuild my 4CCO last year.

As it turns out, I completely replaced the wiring, relays, diode, breaker and the control board with original components. It runs great now . . . . I hope for a good while.

).

).