- Joined

- Jun 25, 2008

- Messages

- 10,104

- Location

- Australia

- Vessel Name

- Now boatless - sold 6/2018

- Vessel Make

- Had a Clipper (CHB) 34

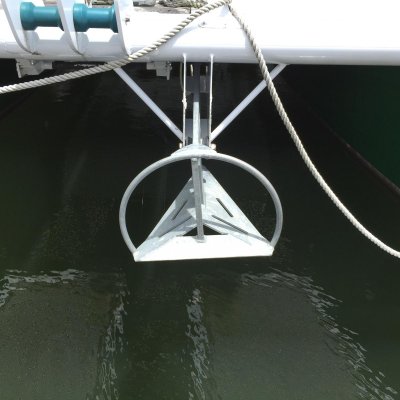

Eric, it probably lands upright or on its side about 50:50, TBH. In soft mud, Rex is sure, and I tend to agree, that because the SS roll bar slants a bit towards the direction of pull, whereas the roll bar of the Rocna slants slightly away from the direction of pull, with the Manson Supreme, (I think) in a more or less neutral plane, that this may be why if the Rocna lands on its back in very soft goo, like in that Fortress series, it might just grab so much mud it stays upside down and drags. A quick re-set in the normal situation would probably sort that out I suspect, because like when I picked up that rock, it would be pretty obvious.

With the SS bar slanting in the direction of pull, assisted by that small triangular secondary fluke adjacent the roll bar, if it landed wrong way up in soft mud, would tend to still pivot it over onto its side and then quickly catch the bottom, rotate, and dig in as usual. The Manson performed better, so I suspect that might have been luck, or because of the roll bar not slanting so much away from the shank as the Rocna's. Pity you hacked off that Manson roll bar, or you could check that point out for us. Still, if we scroll back a few pages to where Steve has all the anchors laid out in his cabin, we might be able to compare that bar orientation to see if I'm right..?

This is why Steve's tests are going to be so interesting.

PS. It appears Steve does not have a Rocna there, but the Manson roll bar definitely looks like it is near vertical to the fluke. The Mantus is hard to gauge because of where it is and the angle.

With the SS bar slanting in the direction of pull, assisted by that small triangular secondary fluke adjacent the roll bar, if it landed wrong way up in soft mud, would tend to still pivot it over onto its side and then quickly catch the bottom, rotate, and dig in as usual. The Manson performed better, so I suspect that might have been luck, or because of the roll bar not slanting so much away from the shank as the Rocna's. Pity you hacked off that Manson roll bar, or you could check that point out for us. Still, if we scroll back a few pages to where Steve has all the anchors laid out in his cabin, we might be able to compare that bar orientation to see if I'm right..?

This is why Steve's tests are going to be so interesting.

PS. It appears Steve does not have a Rocna there, but the Manson roll bar definitely looks like it is near vertical to the fluke. The Mantus is hard to gauge because of where it is and the angle.

Last edited: