My wash down pump is made by Jabsco Model 11810.

I have it mounted near gen set in the lazarette.

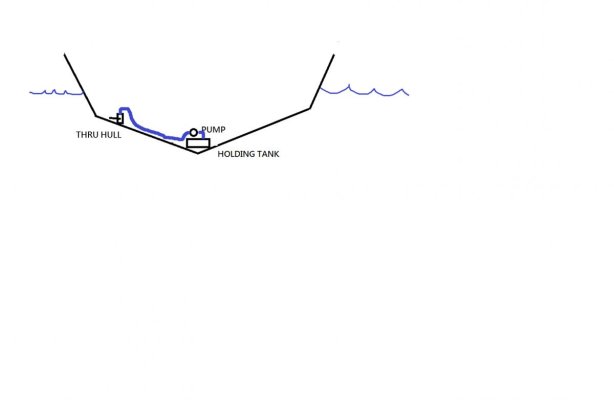

Seawater is shared with the cruisair heat pump thru-hull with a 't' fitting.

From the pump, I split off a 't' to a rear wash down hose and nozzle.

For the anchor washdown, I snaked a 1/2 inch old garden hose through the bilge all the way to the bow. I had to drill through one bulkhead, then resealed it with a polyurethane sealant. I suppose 1/2 inch cuts the flow a little from 3/4.

I brought the hose up into the anchor locker where the anchor line lays. Joined hose to a ribbed flex dishwasher output hose. That ribbed hose I passed through a PVC fitting glued into the deck. The ribbed hose can easily pull up maybe 6 feet and go back down, so it slides in and out for storage. A screw on type walmart hose end is attached to the ribbed dishwasher hose (they have rubber ends which happened to fit with a little cutting a hose end). Then onto a quick disconnect fitting that has a turn valve and the plastic nozzle.

I still find the chesapeake bay mud to be like a sticky glue, so I may have to push it off manually. I was able to do this project for very low cost, which is why I did so, otherwise I don't know if I would have.

Here is a picture in the bow. I guess I left a coil here since at the time was not sure how well that dishwasher discharge hose would work.

I used this for a quick disconnect up on deck.

Amazon.com: Camco 20103 Quick Hose Connect with Shutoff Valve: Automotive

I already had this pump on the boat when I bought it back in 1998.

https://jet.com/product/detail/9d2e...cr8Jw0RN_bryd1tuVZ8SQe8AAOHJB9JW_kaAqrs8P8HAQ

To me it is an outrageous pump price. It does work pretty good. i replaced the impeller with one made by Globe. I would have never bought this pump myself.

If anyone gets one, make sure the impeller and shaft are greased up so it can not rust into the motor shaft. I had to torch and cut off the old SS impeller core from the shaft. Awful, just terrible. I had to use a core drill to cut out the rubber first.

The OEM seal is no good for long life. It will leak and lock impeller to motor shaft.

I got an all rubber seal for a few dollars, then I replaced the metal spring with an o-ring. It has been trouble free now for years.