cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

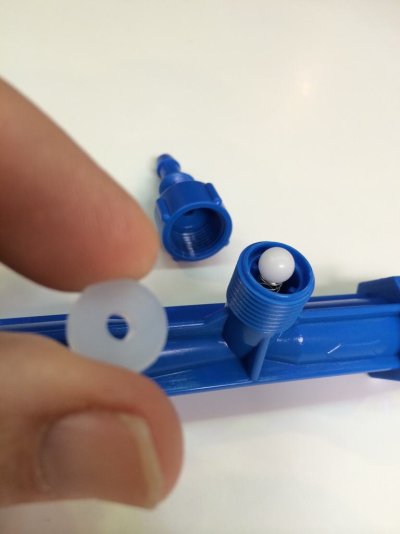

I bought this little venturi pump to try to hook up to my Ac drain. It currently drains into the center bilge area and the bilge pump can't get it all out. Stays wet all the time.

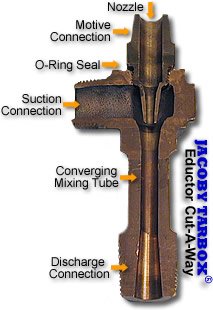

My plan was to put this pump inline on my AC raw water cooling line and hook the drain to the auction side. However, I noticed the restriction in the AC raw water line is pretty severe (see tiny hole in pump pic). Think that will cause too much back pressure on AC raw water line?

There is really no room to run the drain overboard due to the center location of the bilge area.

Last edited: